3 Steps to Calculate Required Reactive Power for PF correction

3 Steps to Calculate Required Reactive Power for PF correction https://www.theelectricalguy.in/wp-content/uploads/2020/06/06-1024x576.jpeg 1024 576 Gaurav J Gaurav J https://secure.gravatar.com/avatar/87a2d2e0182faacb2e003da0504ad293?s=96&d=mm&r=gIf you think calculating required reactive power for power factor correction is a difficult task, then this tutorial will prove you wrong. In this tutorial, I’ll be demonstrating you, 3 steps to calculate required reactive power for power factor correction. Also at the end, you’ll get a link for a simple excel tool which you can download and use to automatically calculate the required reactive power. So, let’s start.

Check out the previous tutorials of Power factor series.

Before you start calculating the required reactive power you must know two things –

- Current power factor for your machine or system

- Total power in kW

If you know these two parameters, you are good to go.

Required Reactive Power

Let’s say you have a 100kW induction motor whose current power factor is 0.7, and you want it to be 0.95. So, we’ll do our calculations to improve the power factor of this motor. The formula which we are going to use to calculate required reactive power, is given below.

Required reactive power = P x [ tan (cos -I Ø1) – tan (cos -I Ø2)]

Where, P = total power in kW

Ø1 = Current power factor

Ø2 = Required power factor

We’ll break this formula in three simple steps.

Step 1

Calculate the cos inverse of current and required power factor.

In our case, current power factor is 0.7 & required power factor is 0.95

So, the cos inverse of Ø1 is 45.57 & Ø2 is 18.19

Step 2

Multiply the resultant values by tan, and then subtract.

= tan (45.57) – tan (18.19)

= 0.6915

Step 3

Multiply the final value by power.

Now in final step multiply the value obtained from previous step with power.

= 100 X 0.6915

= 69.15 kVAR

So, this much amount of reactive power you’ll need to improve the PF from 0.7 to 0.95. You can select capacitor ranging from 75 kVAR to 80 kVAR to be on safe side.

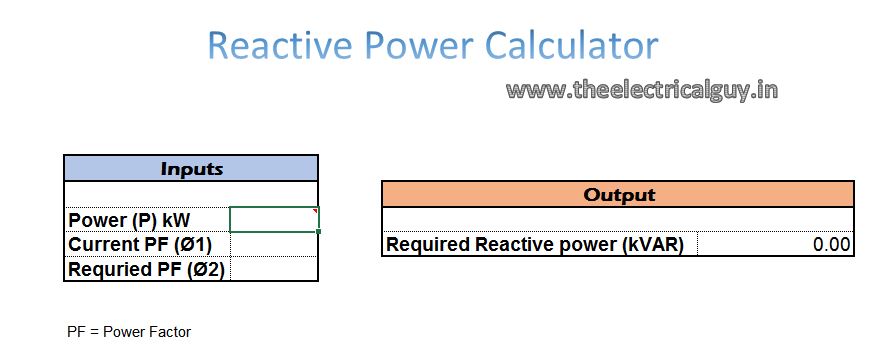

You can also do the same using a simple excel tool that I have created. Simply put the power in kW, current power factor & required power factor in the input filled and there you go, you’ll get the required reactive power.

Click on the link given below to download the excel tool.

- Post Tags:

- Power Factor

- Reactive power

- Posted In:

- Power Factor

- Tutorials

Gaurav J

Electrical Engineer. Content Creator. Currently working with a High & Extra High Voltage Switchgear Industry.

All stories by: Gaurav J