What is Substation Grounding & How It’s Done

What is Substation Grounding & How It’s Done https://www.theelectricalguy.in/wp-content/uploads/2025/12/maxresdefault-2-1024x576.jpg 1024 576 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gHave you ever wondered why substations stay safe even when they carry huge currents? Engineers walk inside them without fear, despite thousands of amperes flowing under their feet. You may also notice that most grid faults move harmlessly into the earth. This is not luck. It is a planned safety design. Beneath each substation sits a hidden grounding network. It is out of sight, yet it protects life and equipment every second.

This article explains these basics in a simple way. You will learn what grounding means, why it matters, and how substations build it. You will also learn about step potential and touch potential. These two ideas define the main risks that grounding prevents.

Table of Contents

- Understanding Earthing and Grounding in Substation Grounding Basics

- Why Substation Grounding Is Critical for Safety

- How Substation Grounding Works in Practice

- Modern Advancements in Substation Grounding

- Step Potential in Substation Grounding Basics

- Touch Potential in Substation Grounding Basics

- Conclusion

Understanding Earthing and Grounding in Substation Grounding Basics

People often use the words earthing and grounding as if they mean the same thing. They do not. Both are important, but each has a separate purpose. A simple method helps you remember the difference.

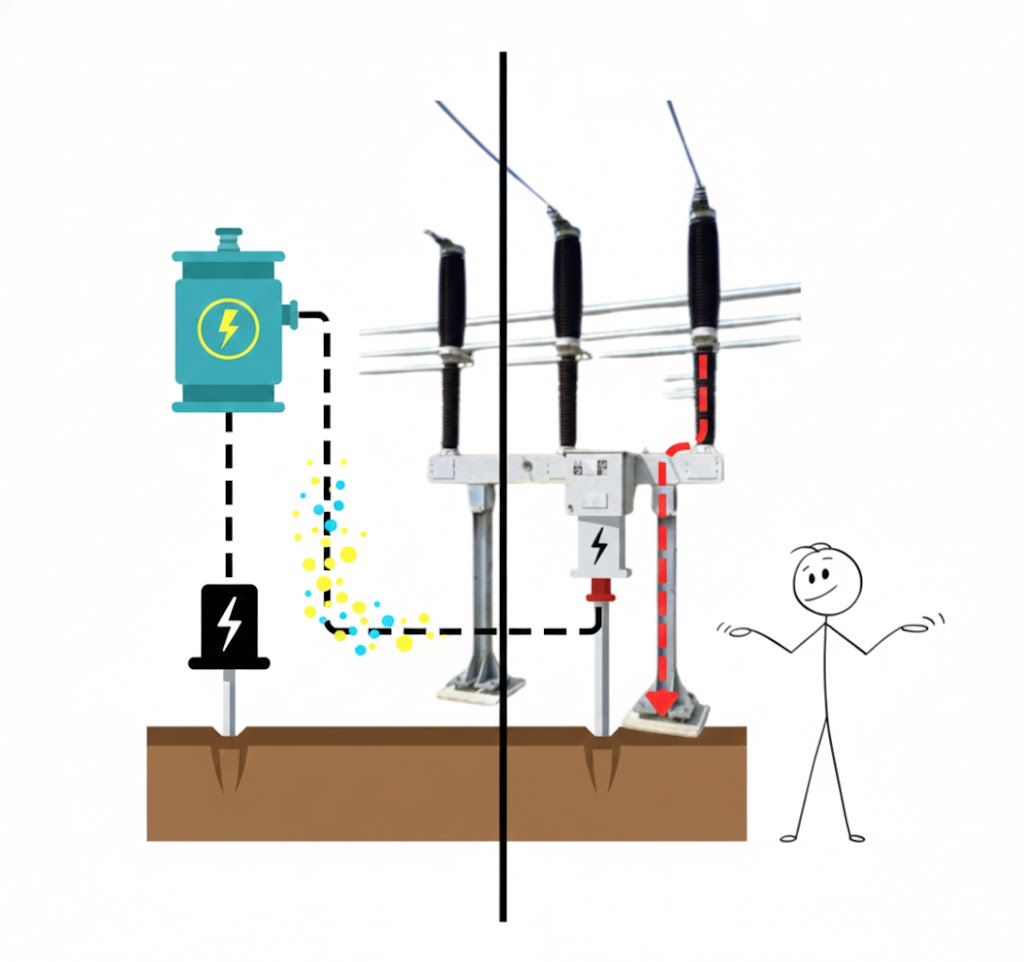

Earthing protects people from equipment. Grounding protects the power system from instability.

What Earthing Means

Earthing connects metal parts of equipment to the soil. The tank of a transformer also needs this link. Frames, structures, and metal shells follow the same rule. Other outer bodies, like those on motors, connect to the earth as well.

This protects people during a fault. When someone touches a metal part, the current must not pass through the body. Earthing ensures the fault current flows into the ground. The earthing path has lower impedance than a human body. So the safer path carries the current. That is why earthing saves lives.

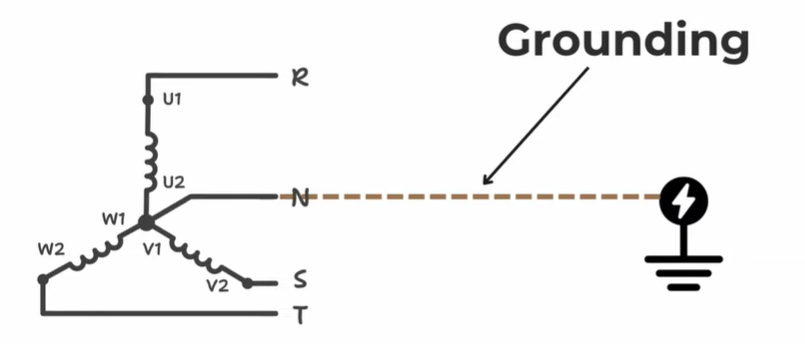

What Grounding Means

Grounding links the system’s neutral point to the earth. This keeps voltage levels stable. It also stops floating voltages from appearing. When faults occur, grounding guides the current safely. Lightning strikes also find a planned return path.

Without grounding, both equipment and people face danger. Faults may cause high voltages. They may damage assets and harm anyone nearby. Grounding is therefore a core safety feature in every substation.

Why Substation Grounding Is Critical for Safety

Substation grounding has three main goals. Each goal is essential for safe and stable operation.

1. Personal Safety

A good grounding system keeps people safe. It controls the current flow during a fault. This prevents dangerous voltages from building up around a person.

2. Voltage Stabilization

Grounding keeps the system voltage steady. It avoids sudden rises or drops. With a stable reference point, the system works smoothly.

3. A Low-Impedance Path for Fault Currents

A grounding network provides a low-impedance route for fault currents. This ensures faults clear quickly. At the same time, it reduces the risk of damage.

If grounding fails, the danger rises. The soil around the substation may develop a high potential. This is known as ground potential rise or GPR. GPR creates unsafe zones around the substation. High GPR levels also create step potential and touch potential. Both can become deadly.

These hazards show why proper grounding is not optional. It is the most important safety measure in any substation.

How Substation Grounding Works in Practice

Now that we know why grounding matters, let us see how engineers build it. The most common method is the earth grid or ground grid.

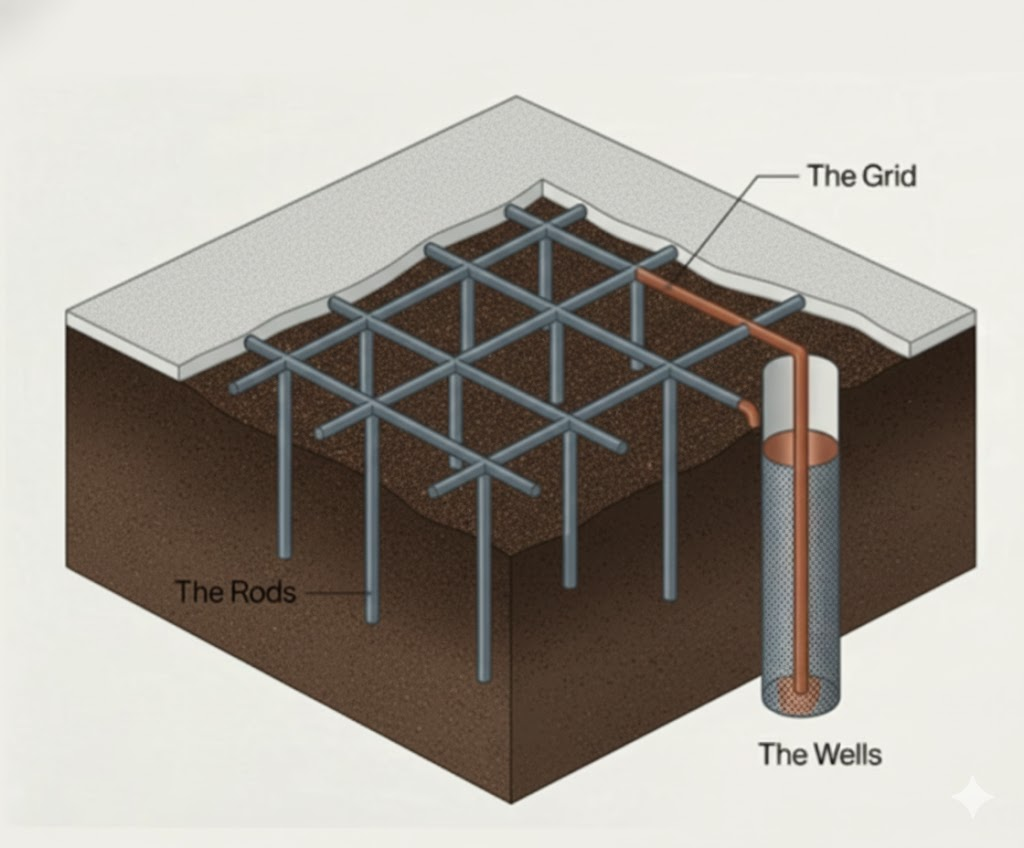

The Earth Grid Method

Engineers install a mesh of copper or GI conductors below the substation yard. These bars or strips form a square-shaped grid. The grid sits one or two feet under the soil. Every substation structure connects to this grid. It covers the yard fully. When faults occur, this grid keeps the ground potential stable. It spreads the current safely. It also prevents sudden voltage changes in the soil.

Where This Method Applies

This method suits outdoor high-voltage substations. It may not suit all sites. Low- and medium-voltage systems do not always need large grids. Their voltage levels are lower, so simpler methods may work.

Indoor substations also work differently. In such systems, the steel bars inside concrete foundations help create the grounding path. GIS substations use this method often. So every substation follows the same idea, but the method varies with voltage, site type, and equipment layout.

Soil Resistivity and Its Impact

Grounding must adapt to the soil. Resistivity changes from place to place. Engineers improve grounding when soil resistivity is high.

Sometimes they add vertical rods. These rods go deeper and improve the grid’s performance. In some places, engineers drill grounding wells. These wells act like boreholes and reach nearly 150 feet. They also hold ground enhancing material, often called GEM. This material lowers resistance and improves safety. These adjustments help meet grounding standards even in poor soil.

Modern Advancements in Substation Grounding

Grounding methods are also evolving. Older substations often lack drawings or layout details. Engineers now use ground-penetrating radars (GPR) to study these sites. These tools scan the soil to locate old grids. They also report aging issues.

Real-time monitoring is another improvement. Sensors track the health of grounding networks. They alert teams when parts degrade or fail. Pre-fabricated grounding grids are also common now. They work like ready-made kits. Teams install them quickly, which saves time and reduces errors. These upgrades make grounding safer and easier to maintain.

Step Potential in Substation Grounding Basics

Step potential is a key safety concern. It appears when the ground grid is weak or faulty. When a person walks in the yard, both feet touch different points. If the soil is energized, each foot may face a different voltage. The difference between these two voltages is the step potential.

Even one meter of distance can create risk. If the potential difference is high, current may pass through the body. This can harm or even kill. Good grounding reduces this danger. It keeps the voltage difference low.

Touch Potential in Substation Grounding Basics

Touch potential is another major hazard. It appears when someone touches an energized structure. The hand touches the structure at one voltage. The feet stand on soil with another voltage. The difference between these two is the touch potential.

A high difference forces current through the body. Good grounding limits this. It keeps all equipment at nearly the same potential as the soil. So the current chooses the grounding path instead of the person.

Both step potential and touch potential depend on grounding quality. If grounding fails, both dangers rise sharply. That is why grounding design, testing, and maintenance matter so much.

Challenges in Testing Grounding Systems

You can test equipment you can touch. You can also inspect cables or breakers you can see. But grounding is hidden under the soil. It is hard to inspect without tools.

Engineers use special tests to check the condition of underground grids. These tests help locate breaks, corrosion, or weak spots. Good testing ensures that grounding stays effective for decades. We will explore how the testing is done in the coming article.

Conclusion

Substation grounding is the silent protector of the power grid. Grounding protects people in the substation. It also keeps the system voltage stable. Dangerous currents move safely into the soil through the grounding path. Without this system in place, substations would turn into unsafe zones.

This article covered the basics of earthing, grounding, earth grids, soil effects, modern methods, step potential, and touch potential. To understand it even better, you can watch the full video linked in the transcript.

- Posted In:

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi