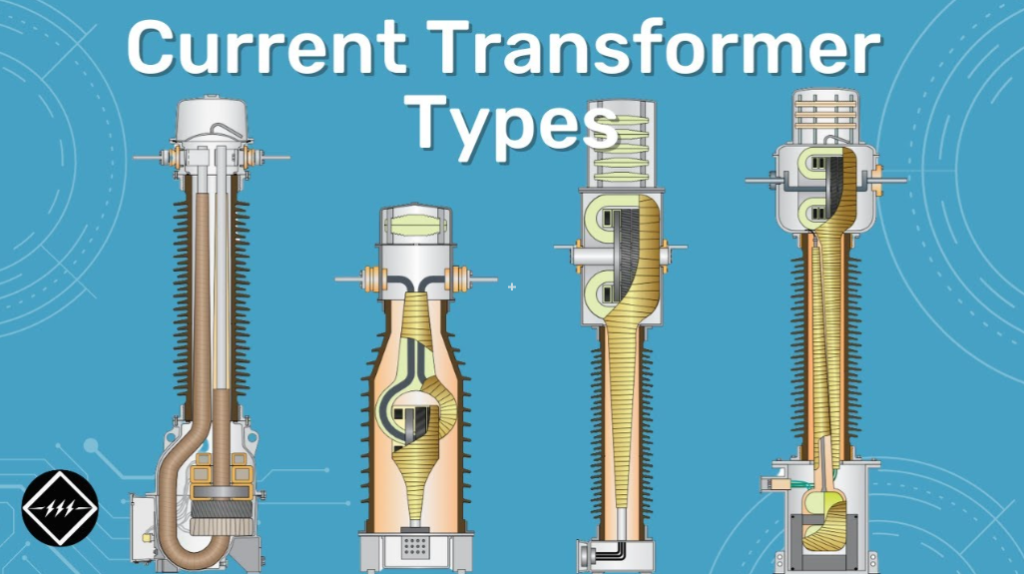

What Are Types of Current Transformers?

What Are Types of Current Transformers? https://www.theelectricalguy.in/wp-content/uploads/2026/02/Screenshot-2026-02-18-210825-1024x574.png 1024 574 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gCurrent transformers play a key role in electrical systems. Engineers use them for measurement and protection. They help reduce high current to safe levels. This reduced current can connect to meters and relays.

Since current transformers serve many purposes, they come in different forms. Each type suits a specific application. Therefore, understanding these types becomes essential. It helps in system design, maintenance, and troubleshooting.

For easy learning, experts divide current transformers into categories. These categories depend on construction, insulation, design, and special applications. This method makes learning simple and logical.

Table of Contents

- Types of Current Transformers Based on Construction

- Easy Method to Remember Construction Types

- Types of Current Transformers Based on Insulation Medium

- Types of Current Transformers Based on Design

- Special Types of Current Transformers

- Summary of Types of Current Transformers

- Conclusion

Types of Current Transformers Based on Construction

Construction forms the foundation of any current transformer. It defines how the primary and secondary interact. It also decides installation flexibility and usage area. Let us now explore the main construction-based types.

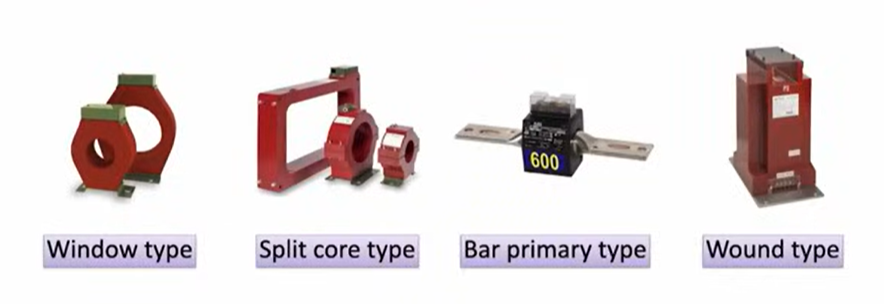

Window Type Current Transformer

The window type current transformer is the most common design. In practice, engineers mainly use it in low and medium voltage switchgear systems. In this design, a hollow opening called a window is provided. The conductor passes through this window. As a result, the conductor acts as the primary winding. No separate primary coil exists.

Instead, only the secondary winding remains inside the core. Because of this simple structure, the design remains reliable and cost-effective. In addition, the window can have different shapes. It may be circular or square. Therefore, the final choice depends on system needs.

In three-phase systems, separate window CTs serve R, Y, and B phases. Each busbar works as a primary conductor. This type offers easy installation. However, it requires access to the conductor during setup.

Split Core Type Current Transformer

The split core type works like the window type. Yet, it has one major advantage. The core can open into two parts. Bolts and nuts hold these parts together. Engineers can loosen them. After that, they can place the CT around an existing conductor.

This design removes the need to disconnect cables. Hence, it becomes useful in retrofitting projects. Maintenance teams often prefer this type. It saves time and reduces downtime. Once installed, technicians tighten the bolts. This ensures proper magnetic contact. Although convenient, it may cost more than standard window types.

Bar Primary Type Current Transformer

The bar primary type also resembles the window design. However, it has a fixed primary bar. This bar comes permanently fitted inside the CT. Users connect external conductors to this bar. Here, the bar acts as the primary winding. The secondary remains wound around the core.

Because of fixed construction, this CT offers better mechanical strength. It suits switchgear applications. However, its price remains higher than window types. Engineers select it only when needed.

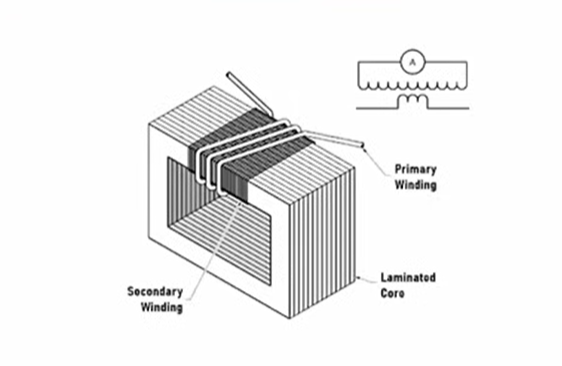

Wound Type Current Transformer

The wound type current transformer has both primary and secondary windings. Both windings sit on the same core. The secondary uses thin wire with many turns. Meanwhile, the primary uses thick wire with few turns.

Primary turns may be one, two, or three. These connect in series with the main conductor. Since the primary is wound, it offers better accuracy. It works well in low-current applications. Additionally, this CT can support conductors. In some cases, it replaces separate bushings. This dual-purpose feature makes it valuable in compact systems.

Easy Method to Remember Construction Types

Remembering CT types becomes easy with logic.

- Window type has a window opening.

- Bar primary type contains a fixed bar.

- Wound type has a wound primary coil.

Understanding these names helps recall their structure. This improves learning and interview performance.

Types of Current Transformers Based on Insulation Medium

Insulation protects CTs from electrical breakdown. It becomes critical at high voltages. Low and medium voltage CTs often use solid insulation. High voltage CTs need special mediums. Let us examine these insulation-based types.

Epoxy Resin Insulated Current Transformers

Most low and medium voltage CTs use epoxy resin insulation. This solid material provides electrical and mechanical strength. These CTs do not require liquid or gas insulation. Hence, maintenance remains simple. They perform well in indoor panels and compact switchgear. However, epoxy cannot handle very high voltages. Therefore, its use remains limited.

Oil Type Current Transformer

Oil type CTs serve high voltage systems. They contain insulating oil inside a metal tank. This oil cools and insulates internal components. It improves voltage withstand capacity. The structure resembles bar primary CTs. A fixed bar passes through oil-filled tanks.

Oil insulation costs less than gas insulation. That makes it popular. Yet, oil has safety risks. Leakage or aging may cause failures. Some substations have reported explosions. Therefore, maintenance becomes critical for oil-filled CTs.

SF6 Gas Insulated Current Transformer

SF6 gas CTs offer higher safety and reliability. They use sulfur hexafluoride gas for insulation. This gas has excellent dielectric strength. It prevents internal discharges. Such CTs appear in modern substations. They work well in compact layouts. Compared to oil types, they offer better fire safety. They also require less maintenance. However, they cost more. Engineers select them when reliability matters most.

Types of Current Transformers Based on Design

Design-based classification applies mainly to high and extra-high voltage CTs. These designs manage mechanical stress and heat. Let us explore these special structures.

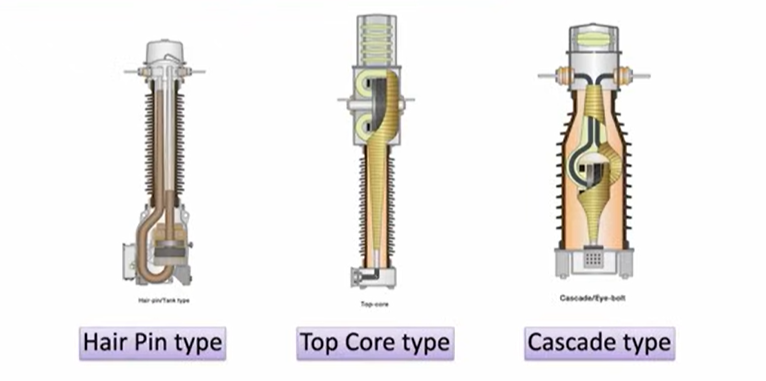

Hairpin Type Current Transformer

In hairpin type CTs, the primary conductor bends like a hairpin. It enters, loops, and exits. Secondary cores sit in the bottom tank. All weight stays near ground level. This reduces stress on porcelain insulators. Hence, mechanical stability improves. However, the long conductor causes heating problems. Thermal stress reduces lifespan. Due to this issue, usage remains limited.

Top Core Type Current Transformer

The top core type remains the most popular design. Most modern substations use it. In this type, secondary cores stay in the top tank. A short primary bar passes through them. This reduces thermal issues. Short conductors dissipate heat better.

Yet, this design adds weight at the top. Therefore, it needs strong porcelain or silicone insulators. Despite this, engineers prefer it due to reliability.

Cascade or Eyebolt Type Current Transformer

The cascade design sits between hairpin and top core types. Here, secondary cores lie in the middle section. The conductor passes through them. This design reduces thermal stress compared to hairpin type. Still, it remains higher than top core design. It also needs taller insulators. This increases cost and installation complexity. Hence, this type appears less frequently.

Special Types of Current Transformers

Some CTs serve unique purposes. These fall under special category types. They support portable testing, space-saving designs, and modern digital systems.

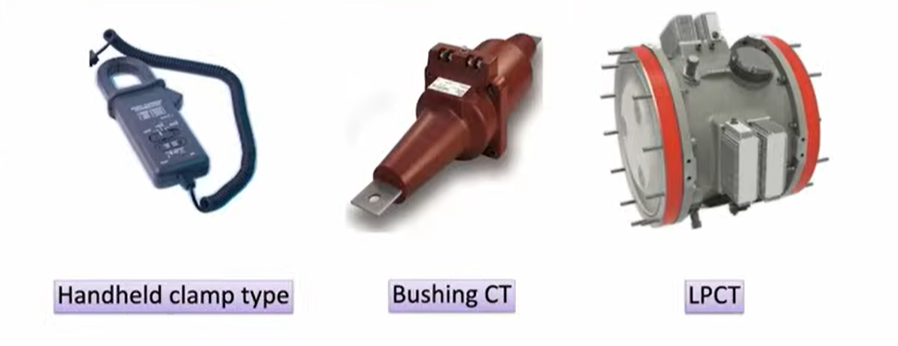

Handheld Clamp Type Current Transformer

Handheld clamp CTs are portable devices. Engineers use them for field measurements. Pressing a lever opens the core. Then, technicians place it around a conductor. After releasing, the core closes automatically. These CTs resemble split core designs. However, they remain lightweight. They work well for maintenance checks. Yet, they handle limited current ranges.

Bushing Current Transformer

Bushing CTs combine two functions. They act as both bushing and transformer. Power transformers use bushings for cable entry. Inside these bushings, CTs get installed. This saves space. It also reduces equipment count. The central portion contains CT cores. Surrounding material provides insulation. However, size limits restrict the number of cores. Usually, only one or two cores fit. High voltage systems may allow more cores.

Low Power Current Transformer (LPCT)

LPCT represents modern CT technology. It works with low power instrument transformers. These CTs use Rogowski coil principles. They measure current without heavy magnetic cores. As a result, they remain very compact. They suit GIS substations and digital systems. LPCTs reduce bay length significantly. They save space and cost. For example, traditional bays may reach 5.5 meters. LPCT-based bays may reduce to 3.7 meters. This advantage makes them popular in smart substations.

Summary of Types of Current Transformers

Let us quickly review the classifications.

Construction:

- Window type

- Split core type

- Bar primary type

- Wound type

Insulation:

- Epoxy resin type

- Oil type

- SF6 gas type

Design:

- Hairpin type

- Top core type

- Cascade type

Special types:

- Handheld clamp type

- Bushing type

- Low power CT

Each type serves specific needs. Engineers must select them carefully.

Conclusion

Current transformers come in many forms. Each design suits a particular voltage level and application. Construction affects installation. Insulation defines safety. Design controls thermal and mechanical behavior. Special types support modern systems.

Understanding these differences helps engineers make better decisions. It also improves system reliability and safety. For deeper understanding, practical visuals, and examples, make sure to watch the original video till the end.

- Posted In:

- Current Transformer

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi