MV Switchgear Parameters: 5 Key Things You Must Know

MV Switchgear Parameters: 5 Key Things You Must Know https://www.theelectricalguy.in/wp-content/uploads/2025/08/maxresdefault-5-1024x576.jpg 1024 576 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gMedium Voltage (MV) switchgear is a critical part of electrical systems. It plays a key role in distributing power safely and reliably between sources and loads. These panels protect equipment, prevent faults from spreading, and safeguard people working around them.

To achieve this, engineers rely on specific ratings and standards that define how the switchgear will perform under different conditions. These ratings ensure that the panel can handle current flow, withstand faults, resist mechanical damage, and stay safe in the long term.

In this article, we will explain the five most important MV switchgear parameters. These parameters apply to the entire cubicle, not just individual devices inside. By understanding them, you can make better choices for design, installation, and maintenance of medium voltage systems.

Table of Contents

- Rated Continuous Current of the Busbar

- Internal Arc Classification

- Busbar Configuration in MV Switchgear

- Rated Short Circuit Braking and Withstand Current

- IP and IK Codes of MV Switchgear

- Summary of MV Switchgear Parameters

- Conclusion

Rated Continuous Current of the Busbar

The first key parameter of MV switchgear is the rated continuous current of the busbar.

- This rating shows how much current the main busbar can carry without issues.

- Typical ratings include 800 A, 1250 A, 2000 A, 2500 A, 3150 A, and 4000 A. For special uses, it can go up to 5000 A.

- The higher the rating, the bigger the switchgear design. For example, 800 A panels are compact, while 4000 A panels are wider.

- At higher ratings, thermal challenges may arise. Sometimes forced cooling is needed.

If a panel is rated at 2000 A:

- It can safely carry up to 2000 A continuously.

- Carrying less, like 1000 A, is fine.

- But carrying more, like 2800 A, creates risks. The busbars cannot handle this load for long.

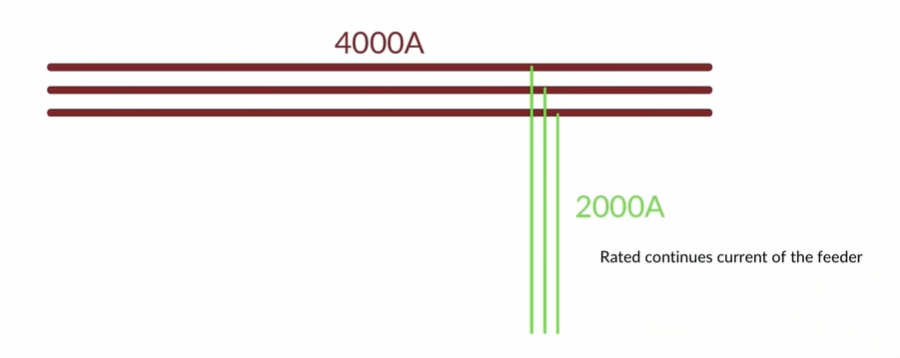

On the nameplate, you may see two current values:

- Rated continuous current of the busbar.

- Rated continuous current of the feeder.

Example:

- The busbar may be rated 4000 A.

- The feeder may be rated 2000 A.

- This is normal because the feeder current depends on the actual load.

IEC standards allow busbars and feeders to have different ratings. The difference reduces cost and matches load demand.

Internal Arc Classification (IA Classification)

Another vital MV switchgear parameter is the internal arc classification. Internal arc faults are dangerous. They can destroy the panel, damage nearby equipment, or even harm people.

- Internal arcs often happen due to loose joints, poor cable connections, or long-term sparking.

- To ensure safety, switchgear is tested for internal arc duty. This is one of the toughest tests.

The nameplate shows the IA rating in a format like AFLR 40 kA 1s.

Meaning of the Letters:

- A – Access only for authorized persons.

- B – Installed in a public area where general people may be present.

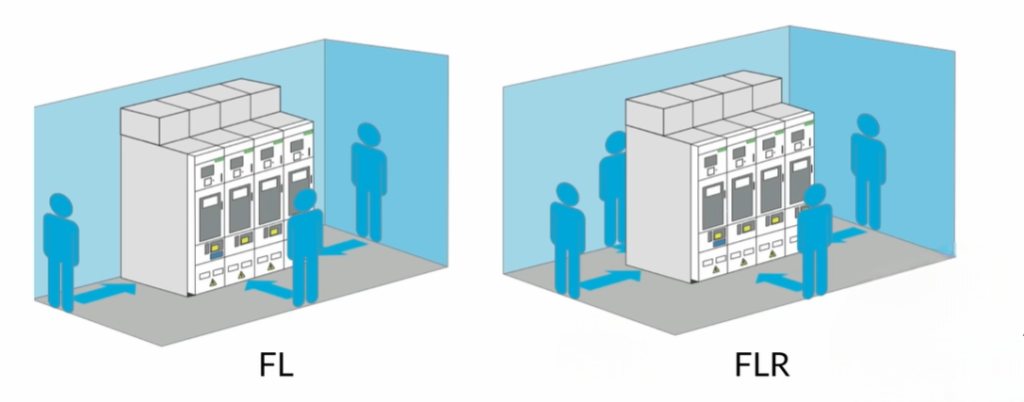

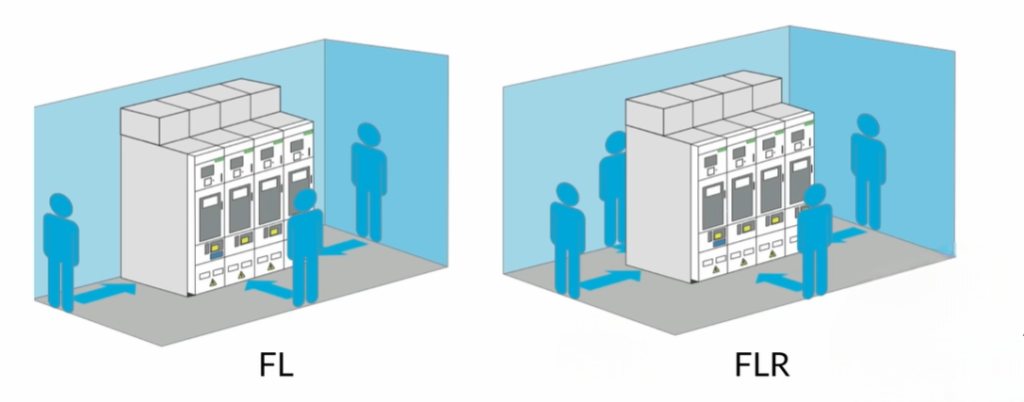

- FLR – Panel tested from the Front, Lateral sides, and Rear.

Current and Time:

- The “40 kA 1s” means the panel withstood a 40 kA arc for 1 second.

- Ducts at the top guide hot gases and smoke safely out of the panel.

Not all panels need AFLR. When the rear is against a wall, testing is for AFL. When space is behind, rear testing is required.

This classification ensures panels remain safe even during worst-case faults.

Busbar Configuration in MV Switchgear

The third important MV switchgear parameter is the busbar configuration.

In high voltage substations, you may find many schemes like double bus, transfer bus, or one-and-a-half breaker. But in MV switchgear, only two are common:

1. Single Busbar Configuration

- Only one busbar is used.

- Simple and widely used.

- Front and side view diagrams show one main bus connected to all feeders.

2. Double Busbar Configuration

- Two separate busbars: Bus A and Bus B.

- Offers higher reliability and redundancy.

- If one bus fails, loads can transfer to the other.

- More costly compared to a single bus system.

The configuration choice depends on application needs and budget. The product data sheet or single-line diagram shows which type is used.

Rated Short Circuit Braking and Withstand Current

The next key MV switchgear parameter is the short circuit rating. This has two parts:

Rated Short Circuit Breaking Capacity

- Assigned to the circuit breaker.

- Shows the ability to break a large fault current.

- Example: 40 kA for 1 second.

Rated Short Circuit Withstand Capacity

- For equipment that cannot break current, like disconnectors.

- They must withstand the fault current until the breaker clears it.

- Example: 40 kA for 1 second.

The difference is simple:

- Breaking = interrupting the fault.

- Withstanding = surviving the fault until cleared.

This ensures all parts of the switchgear remain safe during fault events.

IP and IK Codes of MV Switchgear

The last key MV switchgear parameter is the IP and IK rating.

IP Code – Ingress Protection

- Defines protection of the enclosure against solid objects and water.

- First digit: solids. Second digit: water.

- Common ratings include IP20, IP31, IP43, IP54, IP55, and IP65.

- For outdoor use, IP54 or IP55 is often preferred.

- In Gas-Insulated Switchgear (GIS), two ratings may exist. One applies to the tank. Another applies to the outer cubicle.

IK Code – Mechanical Impact Protection

- Defines resistance against external impacts.

- Protects against accidental collisions, vandalism, or tampering.

- Ratings like IK05 or higher indicate the strength of the panel.

IP and IK codes ensure the enclosure is strong against environmental and physical damage.

Summary of MV Switchgear Parameters

We covered the five most important MV switchgear parameters:

- Rated Continuous Current – Capacity of busbars and feeders to carry load safely.

- Internal Arc Classification – Safety against internal arc faults.

- Busbar Configuration – Single or double arrangement for reliability.

- Short Circuit Ratings – Breaking capacity for breakers and withstand capacity for other devices.

- IP and IK Codes – Protection against dust, water, and mechanical impacts.

Each parameter ensures safe and reliable operation of MV switchgear in different environments.

Conclusion

Understanding these MV switchgear parameters helps engineers design and select the right panels. Each rating reflects safety, reliability, and performance. For a more detailed explanation with diagrams, watch the original video. It shows the concepts visually and makes them even easier to understand.

- Posted In:

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi