What is HVDC Gas Insulated Switchgear? Working and Key Components

What is HVDC Gas Insulated Switchgear? Working and Key Components https://www.theelectricalguy.in/wp-content/uploads/2026/01/maxresdefault-4-1024x576.jpg 1024 576 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gHVDC Gas Insulated Switchgear often surprises beginners. The biggest reason is simple. There is no circuit breaker in the DC switchyard. This leads to many questions. How does switching happen? How are faults controlled?

This article explains HVDC Gas Insulated Switchgear step by step, using a simple tone and clear flow. The explanation follows the same order as the video. Each section builds on the previous one. This makes the topic easier to understand.

Table of Contents

- Why HVDC Transmission Is Preferred in Certain Applications

- Basic Structure and Advantages of an HVDC System

- Need for Switchgear in HVDC Systems

- Why Space Becomes a Challenge with DC AIS

- Introduction to HVDC Gas Insulated Switchgear

- What HVDC Gas Insulated Switchgear Is Made Of

- Main Components of HVDC Gas Insulated Switchgear

- Ratings and Technical Capabilities of HVDC GIS

- Why There Is No Circuit Breaker in HVDC Gas Insulated Switchgear

- Conclusion

Why HVDC Transmission Is Preferred in Certain Applications

HVDC transmission has clear advantages over AC transmission. These advantages appear in specific situations. One major example is offshore power transmission. Another example is long-distance bulk power transfer.

In AC systems, distance creates limitations. Inductive and capacitive effects increase with length. These effects restrict how much power can travel. HVDC transmission removes these issues. Reactive power does not exist in DC systems. Because of this, long-distance transmission becomes efficient.

HVDC also becomes essential when two regions operate at different frequencies. One grid may run at 50 Hz. Another may run at 60 Hz. AC systems cannot connect such grids directly. HVDC provides the only practical link in this case.

Because of these reasons, many HVDC projects already operate worldwide. Many more are currently under development.

Basic Structure and Advantages of an HVDC System

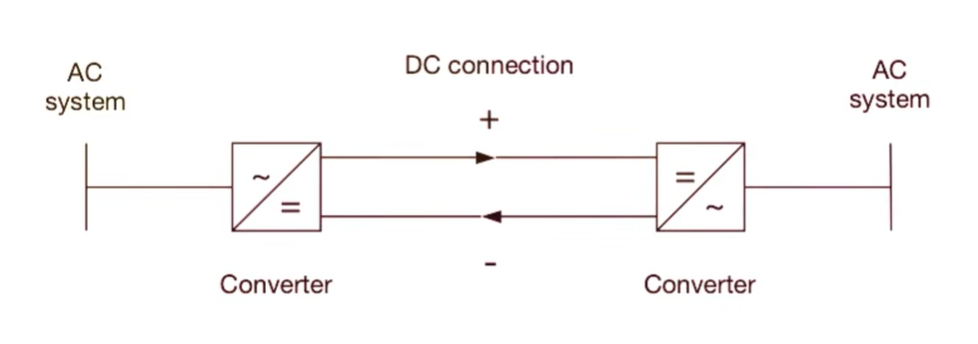

An HVDC system starts with an AC network. A converter station changes AC into DC. This DC power travels through transmission lines. At the receiving end, another converter converts DC back into AC. The AC power then connects to the grid.

This structure allows strong control over power flow. Operators can control direction easily. Power can flow from end to end or reverse when needed. This control improves system stability.

HVDC transmission also offers several advantages:

- No practical limit on transmission length

- Precise control of power flow

- Higher power transfer capability

- Simplified tower design using only two conductors

Since HVDC uses only positive and negative conductors, tower structures become simpler. This reduces construction complexity and cost.

Need for Switchgear in HVDC Systems

Like any power system, HVDC systems need switchgear. On the AC side, engineers use conventional AC switchgear. This switchgear uses either air insulation or gas insulation.

After the converter station, DC switchgear becomes necessary. This switchgear handles direct current instead of alternating current. Similar to AC systems, DC systems also offer two options:

- Air Insulated Switchgear (AIS)

- Gas Insulated Switchgear (GIS)

DC AIS is commonly used because of lower cost. It performs reliably. However, it has one major drawback.

Why Space Becomes a Challenge with DC AIS

DC AIS uses air as the insulating medium. Air has low dielectric strength. Because of this, large clearances are required. These clearances demand large land areas.

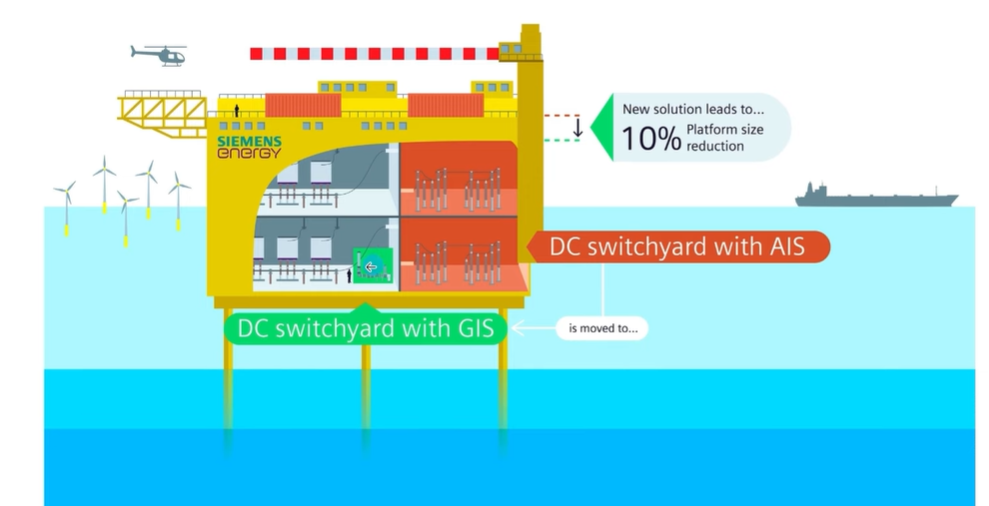

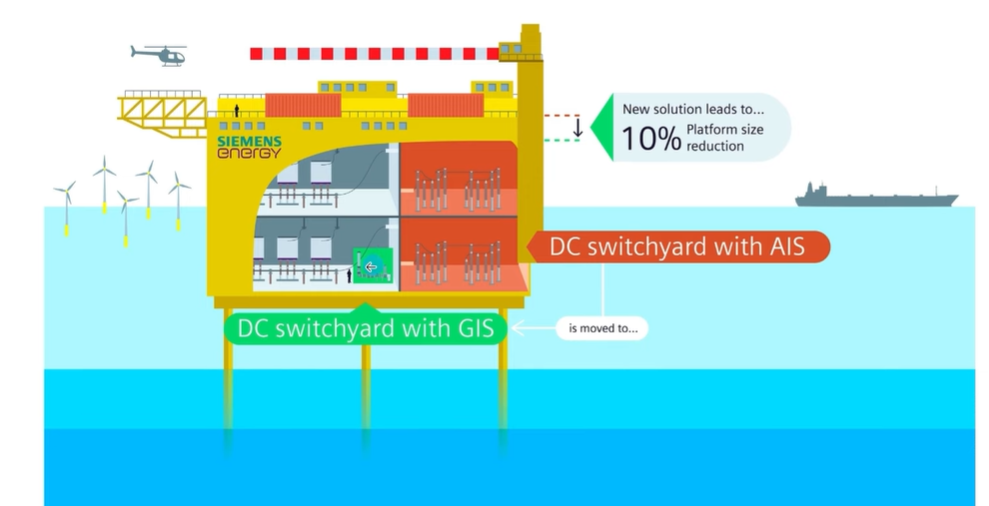

In populated cities, land is expensive. Acquiring such large spaces increases project cost. Offshore projects face even bigger issues. Platforms have limited space by design.

Installing DC AIS offshore requires large platforms. These platforms need more steel and concrete. This increases construction weight and cost. Because of these challenges, space becomes a critical factor.

This is where HVDC Gas Insulated Switchgear becomes useful.

Introduction to HVDC Gas Insulated Switchgear

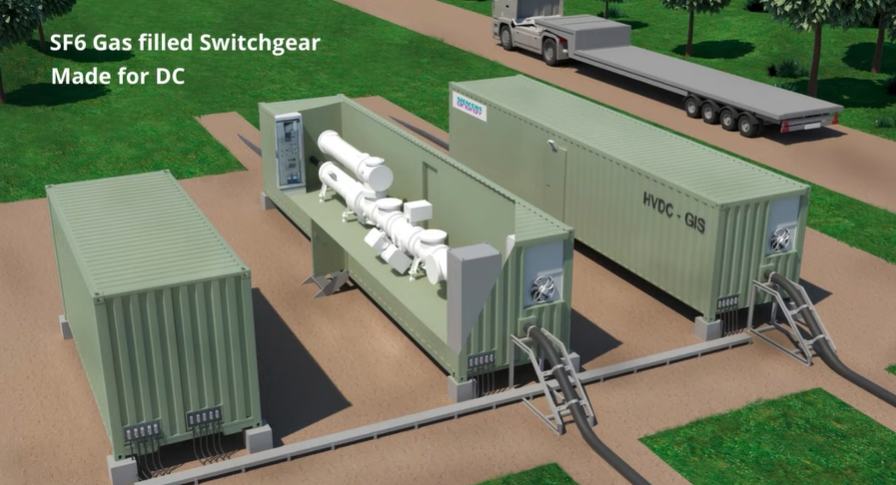

HVDC Gas Insulated Switchgear saves space by design. It uses SF6 gas as the insulating medium. SF6 offers very high dielectric strength. This strength allows engineers to place components much closer together.

Manufacturers claim space savings of up to 95 percent. Visual comparisons show this clearly. DC AIS yards appear wide and open. DC GIS installations look compact and enclosed.

For offshore platforms, this difference is critical. The platform size reduces significantly. Structural requirements also decrease. This leads to major cost savings.

HVDC GIS can be installed in different ways:

- Above ground installations

- Underground installations

- Containerized GIS solutions

Containerized systems arrive ready to install. This improves speed and flexibility during project execution.

What HVDC Gas Insulated Switchgear Is Made Of

HVDC Gas Insulated Switchgear uses SF6 gas-filled enclosures. The gas provides insulation and arc suppression. While the concept resembles AC GIS, the design is different.

HVDC GIS works only with direct current. AC GIS cannot operate in DC systems. DC behavior differs from AC behavior. Therefore, HVDC GIS requires dedicated design.

The main components focus on isolation and safety rather than interruption.

Main Components of HVDC Gas Insulated Switchgear

The most important components in HVDC Gas Insulated Switchgear include disconnectors and earthing switches. These replace the role played by circuit breakers in AC systems.

Disconnectors cannot interrupt live current. They operate only when the system is de-energized. Their main role is isolation during maintenance.

Earthing switches provide safety. They discharge trapped charges by grounding them. This ensures safe working conditions.

Other key components include:

- Surge arresters to protect against overvoltage

- Voltage and current measurement units

- Interface modules and bushings

Measurement units use resistive and capacitive elements. Transformers are not used because transformers work only with AC.

Interface modules allow connection between GIS and external systems. These include SF6-to-air bushings and SF6-to-oil bushings. They connect GIS to transmission lines, cables, or transformers.

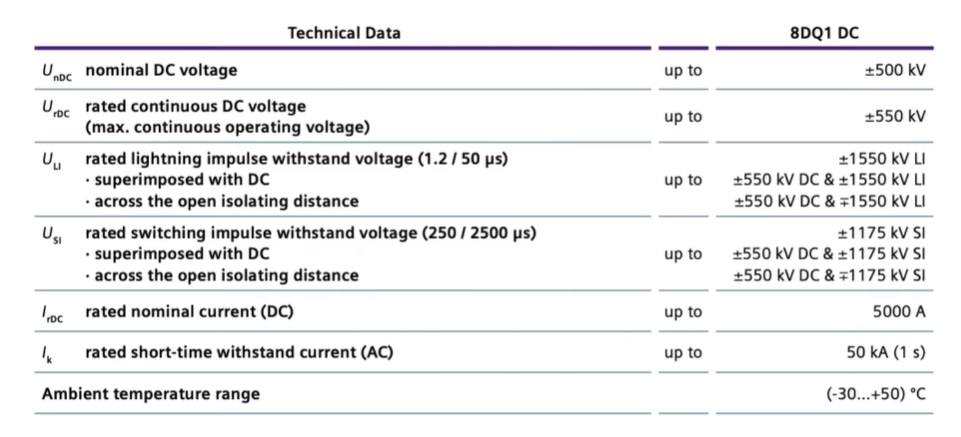

Ratings and Technical Capabilities of HVDC GIS

HVDC Gas Insulated Switchgear operates at very high voltage levels. A common nominal voltage is ±500 kV. The rated continuous voltage can reach ±550 kV.

Nominal voltage represents normal operation. Rated voltage represents the maximum safe limit.

The system also has insulation ratings such as lightning impulse withstand voltage and switching impulse withstand voltage. These ratings protect the system during surges.

Current ratings are equally important:

- Continuous current rating up to 5000 A

- Short-time withstand current of 50 kA for 1 second

This rating does not mean breaking current. It shows how much fault current the system can withstand briefly.

HVDC GIS also operates in harsh environments. Typical temperature range is from -32°C to +50°C.

Why There Is No Circuit Breaker in HVDC Gas Insulated Switchgear

The absence of a circuit breaker stands out as the most important feature of HVDC Gas Insulated Switchgear because the HVDC control system manages protection and operation.

In HVDC systems, converters provide protection and control. Thyristor-based control systems regulate current very quickly. When a fault occurs, the converter reduces or stops the current.

Because the converter controls current electronically and responds quickly, the DC switchyard does not require a DC circuit breaker. The converter itself manages and limits fault currents.

When isolation becomes necessary, operators use AC circuit breakers. These breakers are installed on the AC side of the converter transformer. They disconnect the entire DC system when required.

Breaking DC current is technically difficult. DC has no natural current zero. Some manufacturers offer hybrid DC circuit breakers. However, these systems are complex and costly.

For most HVDC projects, converter-based protection is sufficient.

Conclusion

HVDC Gas Insulated Switchgear plays a vital role in modern power transmission. By reducing the physical footprint, it effectively solves space limitations. Offshore and urban installations benefit greatly from this compact design. Reliable operation is maintained even under harsh environmental conditions.

The absence of a circuit breaker often causes confusion. However, converter-based protection explains this design choice clearly.

To gain a clearer visual understanding of layouts, components, and operation, it is strongly recommended to watch the explained video. Seeing the system makes the concept easier to grasp.

- Posted In:

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi