What Is the Difference Between HV vs MV Switchgear? A Complete Beginner’s Guide

What Is the Difference Between HV vs MV Switchgear? A Complete Beginner’s Guide https://www.theelectricalguy.in/wp-content/uploads/2025/11/maxresdefault-4-1024x576.jpg 1024 576 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gHigh voltage and medium voltage switchgear serve the same purpose. Yet their design differs a lot. Many people enter the power industry without knowing how separate HV and MV systems really are. Both look similar at first, but the internal layout, installation style, and operating method change completely with voltage level.

Because of this, a clear comparison becomes useful for anyone studying, switching roles, or trying to understand substation design. This guide breaks it down step by step so you can follow along without feeling lost.

Table of Contents

- Where We Use HV vs MV Switchgear

- Space Requirement in HV vs MV Switchgear

- Indoor vs Outdoor Use

- Circuit Arrangements

- Busbar Placement

- Breaking Technology

- Purchasing Approach

- Control and Marshalling Systems

- Devices Used in HV vs MV

- Withdrawable Designs

- Supply Termination

- Additional Accessories

- Conclusion

Where We Use HV vs MV Switchgear

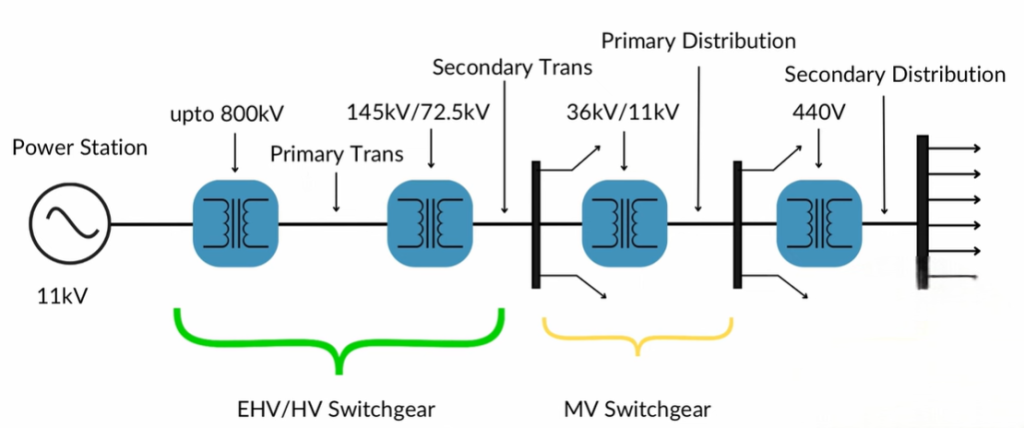

Before we compare both, it is helpful to see where we use them. You can understand this through a basic power system single line diagram.

In the primary and secondary transmission stages, we use high voltage switchgear. These voltage levels can go very high. They can reach up to 800 kV. They can also include levels like 72.5 kV or 52 kV.

However, we use medium voltage switchgear in the distribution stage. This range sits between 52 kV and 1,000 volts. So HV and MV appear in different parts of the system. This is the first major point.

HV vs MV Switchgear: Space Requirement

Why HV Switchgear Needs More Space

The first and most important difference is space. HV switchgear needs a lot of land. The voltage is very high. So if we use air-insulated switchgear, we must keep large clearances. These clearances help maintain dielectric strength. Because of this, HV substations spread across huge outdoor areas.

Why MV Switchgear Is Compact

MV switchgear works with lower voltage levels. So the insulation requirement reduces. As a result, manufacturers can fit MV switchgear inside metal-enclosed panels. These panels can be air-insulated or gas-insulated. Either way, they stay compact. We can place many MV panels inside one small room. This is a major difference between the two.

Indoor vs Outdoor Use in HV vs MV Switchgear

HV switchgear, especially the AIS type, is almost always outdoor. It is not practical to put a huge air-insulated HV substation inside a building. Only GIS-type HV switchgear can be indoor.

In MV, things are different. MV switchgear is usually indoor. It stays safe and compact inside a panel room. It does not matter whether it is AIS or GIS. Most MV systems stay indoors.

Circuit Arrangements in HV vs MV Switchgear

HV Switchgear Has Many Options

In HV systems, you will see many busbar arrangements. Some common ones include:

- Single busbar

- Double busbar

- Main and transfer busbar

- One-and-a-half breaker scheme

These options depend on the substation design. They also depend on reliability needs. HV engineers must choose carefully. So this becomes a crucial point in HV design.

MV Switchgear Uses Only Two Types

In MV, things stay simpler. You will usually see:

- Single busbar

- Double busbar

These two types cover most MV distribution needs. So MV teams do not deal with the wide variety seen in HV systems.

Busbar Placement in HV vs MV Switchgear

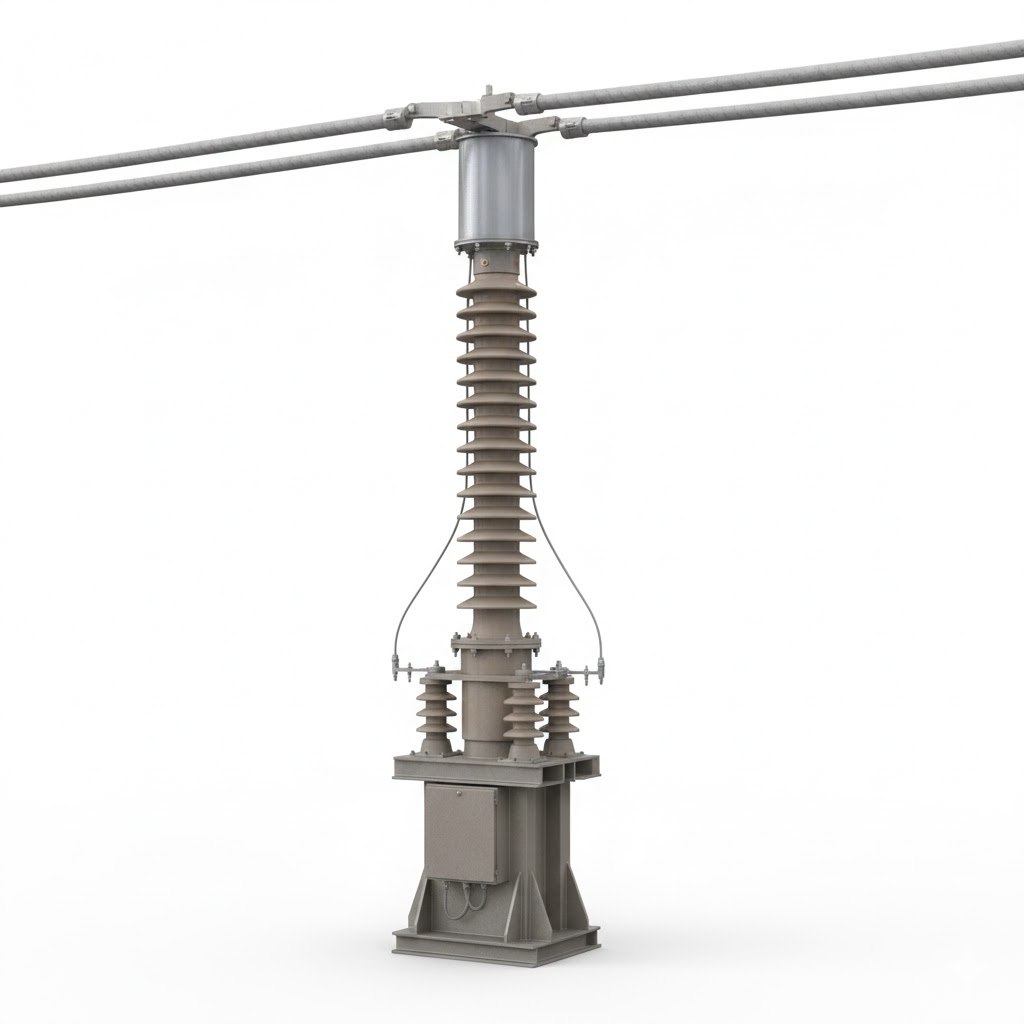

Busbars in HV Systems

In HV AIS systems, busbars stay on the top side of the equipment. These busbars are mostly aluminium. They can be solid bars or hollow tubes. You can see them clearly in outdoor yards. Copper is almost never used in HV. In most cases, the choice is aluminium.

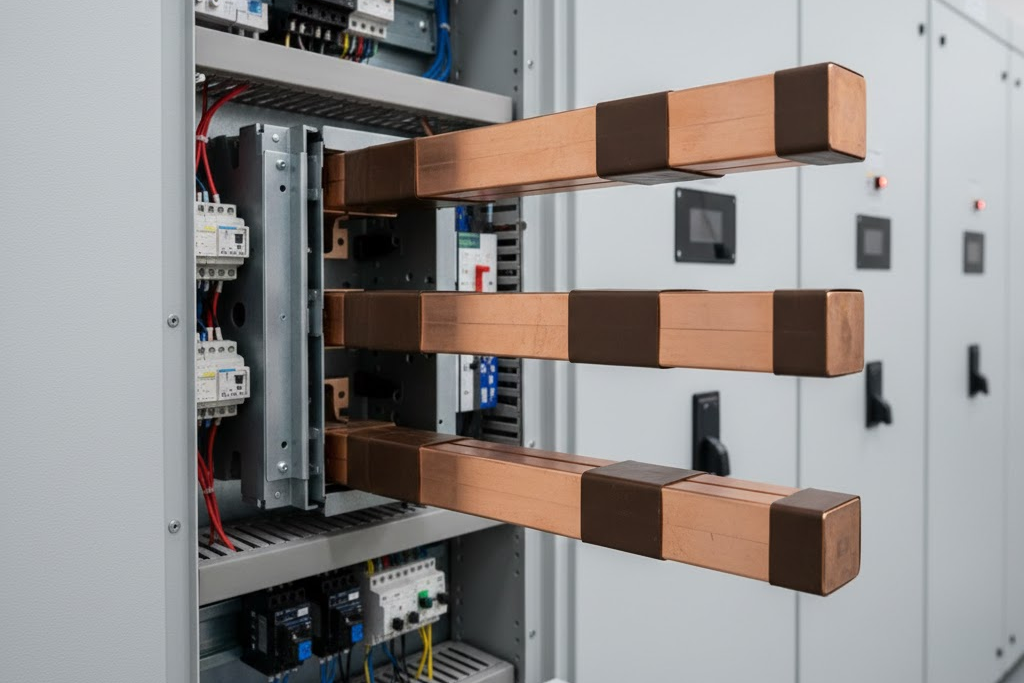

Busbars in MV Systems

In MV systems, busbars stay inside the panel. They form an integral part of the metal enclosure. Manufacturers mostly use copper here. Aluminium is available but less common. Because the voltage is lower, the insulation needed is also small. So busbars fit easily inside compact compartments.

Breaking Technology in HV vs MV Switchgear

HV Uses SF6 but Is Changing Slowly

HV breaking technology has been dominated by SF6 gas. It has high dielectric strength. It works well for high voltage levels.

But the world now wants to reduce SF6 use. So manufacturers are shifting. They are exploring new designs. Vacuum technology is slowly entering HV levels too.

MV Uses Vacuum Technology

MV breaking technology is simpler. It mostly uses vacuum interrupters.

Vacuum breakers work well for MV. They are reliable, compact, and clean. So vacuum dominates the MV market.

Purchasing Approach in HV vs MV Switchgear

HV AIS Allows More Flexibility

HV AIS systems offer high flexibility. You can buy each device from a different manufacturer. For example:

- Buy CT from one supplier

- Buy disconnector from another

- Buy breaker from another

- Buy PT from yet another

So HV AIS systems let you mix and match. However, in GIS-type HV systems, all items come as one unit.

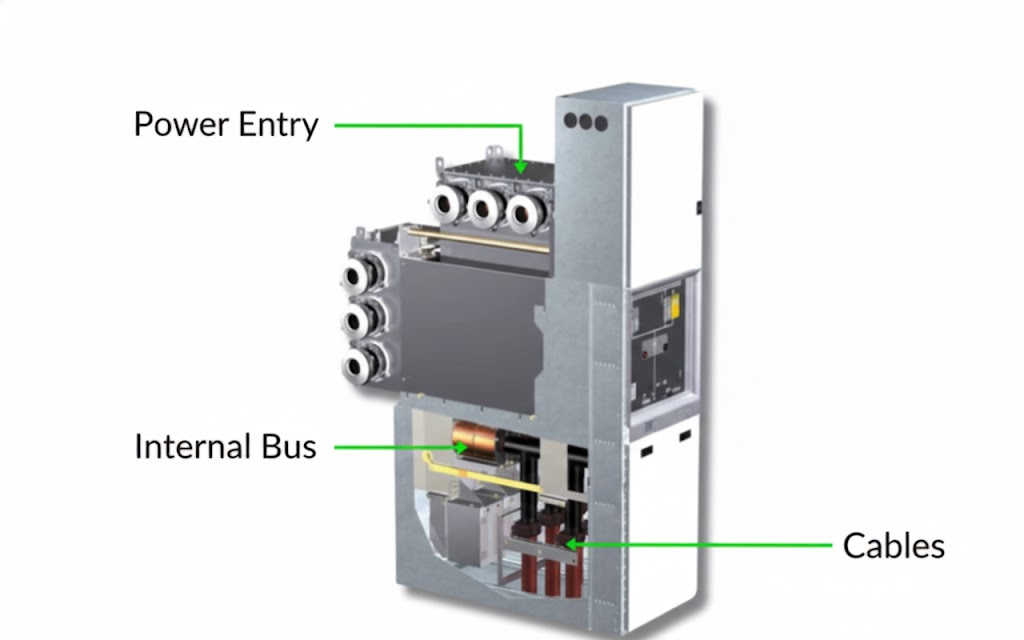

MV Comes as One Complete Panel

In MV, the story changes. MV switchgear comes as one packaged panel. Everything sits inside the metal enclosure:

- CT

- PT

- Breaker

- Busbar

- Control devices

You cannot buy each item from a different brand. You get one complete panel from one manufacturer. So MV offers less flexibility.

Control Boxes and Marshalling in HV vs MV Switchgear

HV Uses Separate Marshalling Boxes

Because HV devices come from different suppliers, each device has its own control box. For example:

- CT has its own marshalling box

- Disconnector has another

- Breaker has its own dedicated box

These boxes hold control wiring. They handle signals and monitoring. Since each device is independent, we also need a control and relay room. This room stores all relays, meters, and control circuits.

MV Has a Single Low-Voltage Compartment

MV switchgear does not need many boxes. All control wiring stays inside one LV compartment. This compartment sits inside the panel. The relays and meters stay on the front door. So MV does not need a separate relay room. This makes MV layouts very simple.

Devices in HV vs MV Switchgear

Devices Found Only in HV

Some devices appear only in HV systems. Two common examples are:

- Wave trap

- Capacitive Voltage Transformer (CVT)

HV uses both inductive and capacitive types of voltage transformers. MV uses only inductive ones.

Devices Found Only in MV

MV uses some devices that HV does not use. Examples include:

- Voltage Detection System (VDS)

- Load break switch

A load break switch can break normal current. HV systems do not use load break switches. They only use circuit breakers for current breaking.

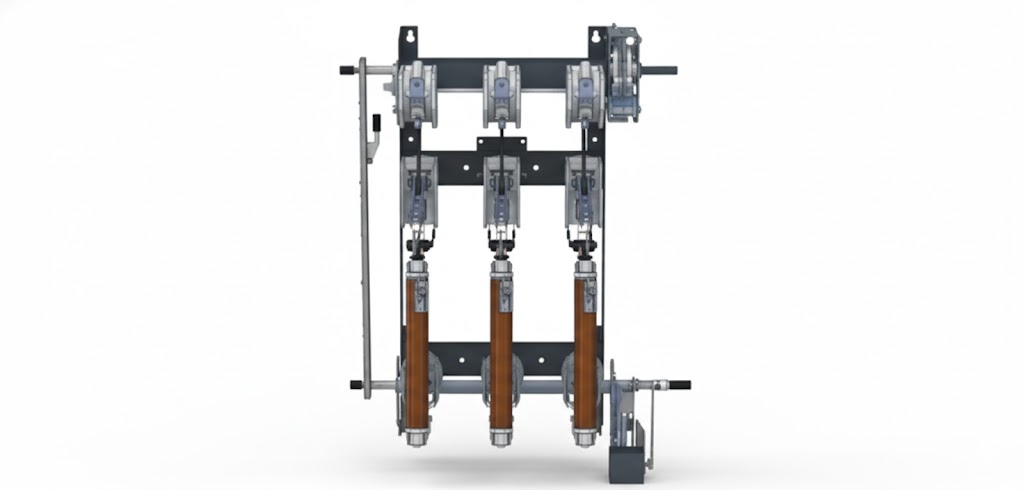

Withdrawable Design in HV vs MV Switchgear

One special feature appears in MV systems. MV switchgear lets you withdraw devices like:

- Circuit breakers

- Voltage transformers

This helps during maintenance. You can slide the device out, replace it, or fix it. The panel stays safe during this process. LV switchgear also uses this feature.

HV switchgear does not offer this option. HV AIS or HV GIS do not include withdrawable designs. High voltage levels make this unsafe. So this feature belongs only to MV and LV.

Supply Termination in HV vs MV Switchgear

Supply Termination in HV

In HV AIS systems, overhead lines provide supply. The incoming lines reach devices through terminal connectors. Each device needs a separate terminal connector. Also, each HV device needs:

- A civil foundation

- A steel support structure

These supports keep the equipment safe in outdoor conditions.

Supply Termination in MV

MV systems use cables for termination. So they do not need terminal connectors like HV. They also do not need heavy steel support structures. A simple base foundation can hold the panel. Cables enter from the bottom and connect directly.

Additional Accessories Needed in HV vs MV

In HV AIS, many accessories support the equipment. These include:

- Jumper connections

- Terminal connectors

- Support structures

- Outdoor foundations

These are essential in HV AIS. Without them, the system cannot work.

MV does not need these things. MV panels sit on one indoor base. The cables bolt directly to terminals. So MV stays clean and simple.

Why HV vs MV Switchgear Causes Confusion

People who shift from HV to MV often feel confused. The layouts differ a lot. The devices differ. The control systems differ. Even the installation style changes. Those who shift from MV to HV face the same confusion.

This comparison helps reduce that confusion. It follows the same points as the video. It also keeps the flow easy to understand.

Conclusion

HV and MV switchgear differ in many ways. The space they need is different. Their designs vary. You can also see clear changes in busbars, breaking methods, and control parts. Devices, terminations, and flexibility levels also change between the two. Yet both share one purpose which is to protect and control the power system.

For a better visual understanding, watch the original video. It explains every part with clear examples.

- Posted In:

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi