How Transformers Control Voltage

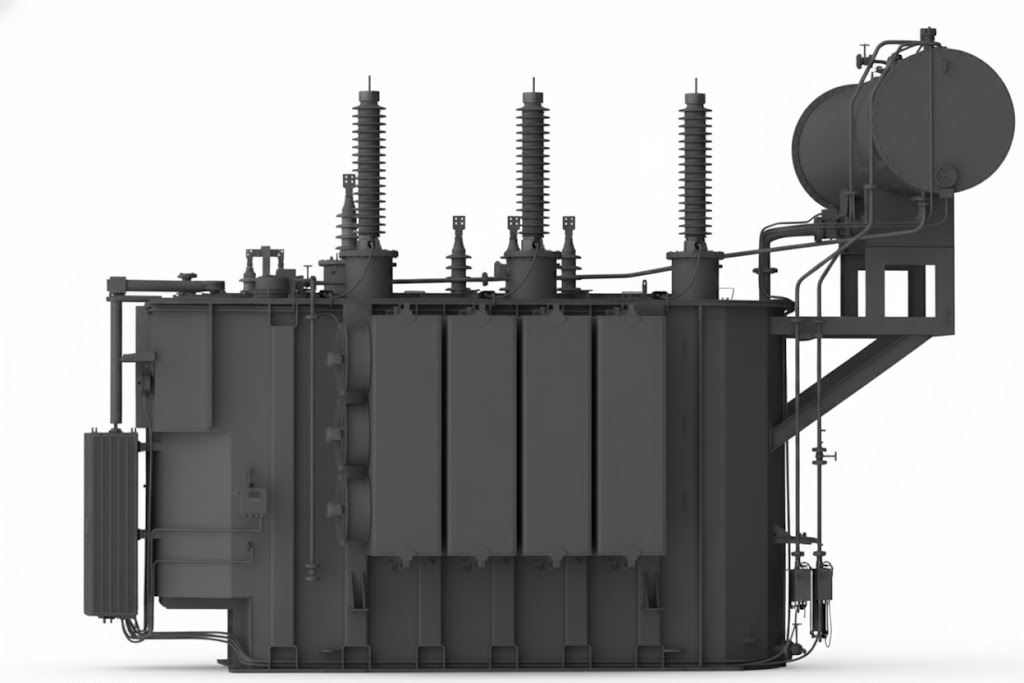

How Transformers Control Voltage https://www.theelectricalguy.in/wp-content/uploads/2025/12/maxresdefault-1-1024x576.jpg 1024 576 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gControlling voltage is vital in any power system. Long lines lose voltage. Loads also cause voltage dips. So we need steady control at many points. One effective tool is the tap-changing transformer. It allows us to control voltage without shutting down the supply. It also helps us maintain stable levels at the load end.

This article explains how transformers control voltage. It follows a simple flow. We begin with the idea of voltage control. Then we move to the turns ratio. Later we look at taps, off-load tap changers, and on-load tap changers. By the end, you will see how these parts work together. You will also see their limits.

Table of Contents

- Need for Voltage Control

- Basics of Voltage Transformation

- Role of Taps in Transformers

- Tap Placement on Transformer Windings

- Off-Load Tap Changing

- On-Load Tap Changing

- Working Flow of Voltage Control

- Advantages and Limitations

- Summary

- Conclusion

Why We Need Voltage Control in Power Systems

In earlier blogs, we explored the need for voltage control. Generator excitation also came up as a useful method in certain cases. Through that, we understood how excitation changes the internal voltage of a generator. However, this method works well only for short transmission lines. Longer lines face larger voltage drops, so excitation alone cannot keep the voltage stable.

Many engineers today also study Battery Energy Storage Systems (BESS), since BESS units also help regulate voltage and support grids. If you want to learn BESS in a structured way, we have a course available. But in this article, our focus stays on transformers and tap changers.

The Basics of How Transformers Control Voltage

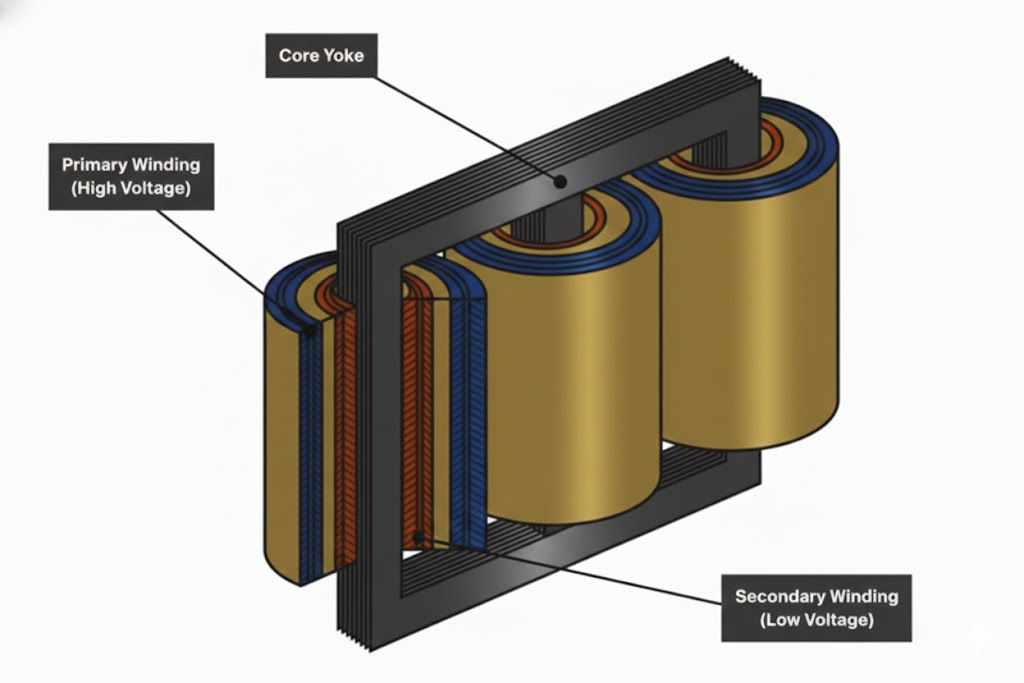

To understand how transformers control voltage, we must first look at the voltage transformation ratio. It links the primary voltage, the secondary voltage, and the number of turns on each winding.

You can express it this way:

- VP is the primary voltage.

- VS is the secondary voltage.

- NP is the primary turns.

- NS is the secondary turns.

If we rearrange the ratio, we can see something clear. The secondary voltage depends on two things. First, it depends on the primary voltage. Second, it depends on the number of turns. We assume the primary voltage stays constant. So only the turns matter.

When we increase the secondary turns, the secondary voltage rises. When we reduce the secondary turns, the voltage falls. On the primary side, the effect is opposite. When we increase the primary turns, the secondary voltage falls. When we reduce them, the voltage rises. This relationship is simple but very important.

Tap changers use this basic idea. They change the effective number of turns. This changes the voltage. And that is the whole principle.

Why We Use Taps on Transformer Windings

A transformer arrives with fixed windings. We cannot open it and add turns. So we use taps. Taps are points on the winding that let us select different numbers of turns. They sit at set positions. If we connect at one tap, we get one value. If we select another tap, we get more or fewer turns.

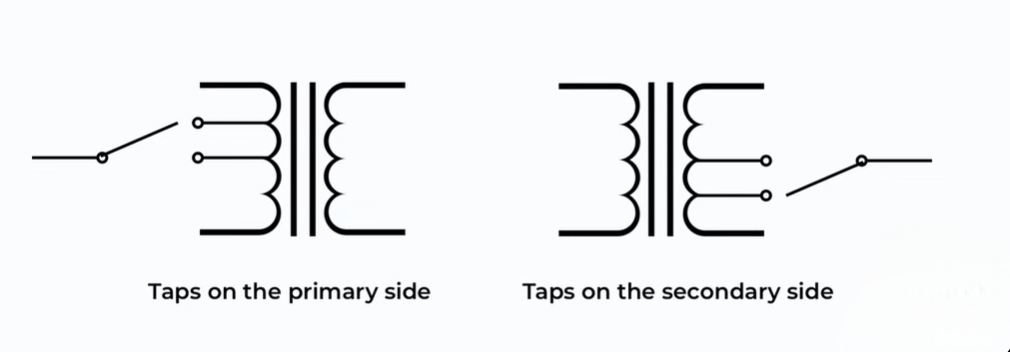

You can place taps on the primary or the secondary side. These give the same result: the ability to adjust voltage. But each side has benefits and limits.

Why Many Taps Are on the Primary Side

Most transmission and distribution transformers have taps on the primary side. This has three main reasons.

First, the primary side has more turns. So we get wider voltage control. We can also add more tap steps.

Second, the primary side sits farther from the core. So adding taps is simpler. On the secondary side, the winding sits near the core. It is hard to create tap points there. So it adds complexity.

Third, the primary side carries lower current. It does have higher voltage. So the insulation needs care. But the lower current makes tap contact easier. On the low-voltage side, currents are high. High current means heat and stress. So large contacts are needed. This makes the design more difficult.

Still, taps on either side can control the voltage. The idea stays the same. The number of turns changes. The voltage follows.

Methods of Changing Taps in a Transformer

There are two methods:

- Off-load tap changing

- On-load tap changing

Both change the turns ratio. But they work in very different ways.

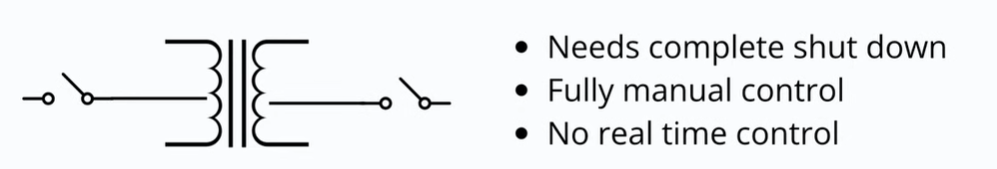

Off-Load Tap Changing in Transformers (How Transformers Control Voltage)

Off-load tap changing is the simpler method. Here, the transformer must be disconnected from supply. We cannot shift taps when the transformer is live. If we try, arcs may form. The system may also face faults. So we first take a shutdown. We isolate both primary and secondary sides.

A simple off-load system uses a rotating knob. When we move the knob, it switches between tap points. Each position selects a new set of turns. This changes the output voltage.

But this method has clear drawbacks.

First, it needs a shutdown. This makes it impractical in many places.

Second, the control is fully manual. We must go to the transformer and change taps.

Third, it cannot handle fast voltage swings. If the voltage rises or falls every few minutes, this system cannot react. It works only in stable conditions.

So off-load tap changers have limited use today. You may still find them in older or small units. But most modern transformers need better control.

On-Load Tap Changing (OLTC) in Transformers (How Transformers Control Voltage)

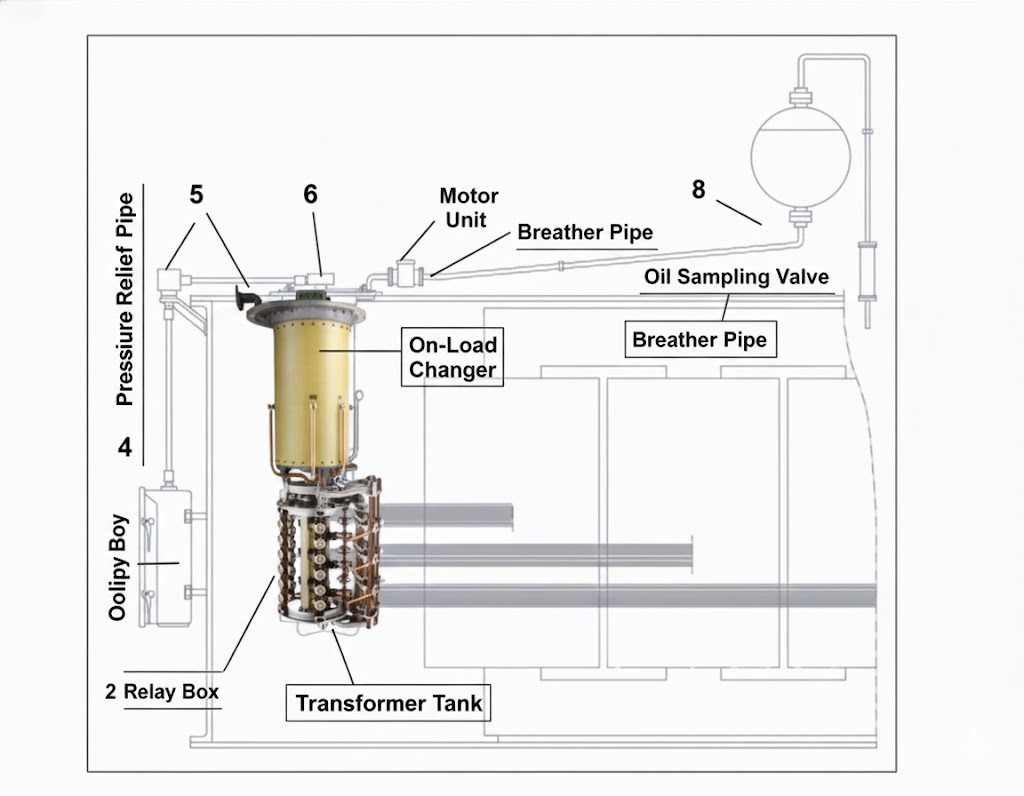

On-load tap changing solves these limits. It allows us to change tap positions when the supply is on. We do not need a shutdown. So we can control voltage in real time.

This type uses a selector switch. It sits inside an oil-filled compartment. It must stay insulated because it works on live voltage. This selector shifts between taps without creating open circuits or arcs. It uses advanced contacts and switching parts.

The tap changer also has an operating mechanism. It is often a motor. It turns the selector as needed. The system can act automatically. It uses a voltage regulator that checks the line voltage at set intervals. If the voltage drifts beyond limits, the regulator sends a command. The tap changer then moves one step up or down.

You may also find a time-delay relay. Voltage may dip or rise for a short time. We should not change taps for small fluctuations. So the relay waits for a set period. If the issue remains, then the tap moves.

OLTC units sit inside the transformer tank. They remain oil-immersed. Some transformers have a separate oil compartment for the OLTC. The insulation must be strong. The mechanical system must also be precise. It has many parts. These parts work under stress. They handle arcs and switching loads.

So OLTC units are complex. They also cost more. Their maintenance takes skill. But the industry has no better method today. They are widely used because they give real-time voltage control without shutdown.

How Transformers Control Voltage Using Tap Changers: Step-By-Step Flow

To see the flow clearly, here is how the process works:

1: The system needs stable voltage.

2: The transformer has taps on its winding.

3: Each tap changes the number of turns.

4: The turns ratio changes the secondary voltage.

5: For off-load systems, we turn off the supply and shift the tap.

6: For on-load systems, the tap changer shifts position while live.

7: A voltage regulator checks the voltage and commands movement.

8: A time delay avoids reacting to brief changes.

9: The tap selector moves a step.

10: The output voltage stabilises.

This is the core idea behind how transformers control voltage. Nothing extra is needed. The full control comes from the turns ratio. The tap changer simply selects the number of turns.

Advantages and Disadvantages of Tap Changing Transformers

Tap changing transformers offer strong benefits. But they also have clear limits.

Advantages

They do not need a shutdown.

On-load tap changers can adjust voltage while the system runs.

Tap changing transformers give steady voltage control. They also react when the load changes. This helps the system maintain voltage within safe limits.

They handle long-distance transmission.

Excitation control alone cannot do this.

Disadvantages

Off-load tap changers need shutdown.

They also lack real-time control.

On-load tap changers are complex.

The large number of moving parts increases complexity. Skilled hands are needed to maintain the unit.

They are expensive.

Both purchase and maintenance cost more.

Even with these limits, OLTC remains the best option today. No other system offers safe, smooth, real-time voltage control inside the transformer itself.

Understanding OLTC Construction in Simple Terms (How Transformers Control Voltage)

Inside the transformer tank, the OLTC sits near the windings. Oil surrounds it. The oil insulates and cools the parts. The selector must avoid open circuits. It shifts between taps using special contacts.

A motor drive sits outside or in a separate chamber. A shaft connects it to the mechanism. When the regulator sends a signal, the motor turns. It moves the tap one step.

The regulator often sits in a control panel. It reads the system voltage. It decides if an upward or downward tap move is needed.

The OLTC must handle high stress. Each shift may create arcs. So it uses arc-quenching chambers. It also uses strong contacts. All these parts make the unit complex.

Why OLTC Is Still the Standard Today

The OLTC is costly and complex. But no cheaper tool can match its value. Power systems need stable voltage. Loads change fast. Weather affects lines. A manual or off-load system cannot keep up. The OLTC remains the only practical solution inside the transformer.

Engineers continue to refine OLTC design. But the core idea stays simple. Change the turns ratio. Control the voltage.

Summary of How Transformers Control Voltage

We started with the need for voltage control. Then we saw the limits of excitation. After that, we studied the turns ratio. We saw how this ratio controls voltage. Then we learned why taps are used. We also saw why most taps sit on the primary side.

Next, we explored off-load tap changers. They need shutdown and give no real-time control. Finally, we studied on-load tap changers. These allow live tap changing. They give fast response. They deliver stable voltage.

This complete flow shows how transformers control voltage using taps and turn ratios. Every step follows the script and does not add extra elements.

Conclusion

Tap changing transformers offer a reliable way to control voltage. They adjust the turns ratio and change the output voltage. Off-load tap changers work only when the supply is off. On-load tap changers work while the system runs. They use regulators, relays, contacts, and oil-immersed parts to operate safely. Because of these many components, the design becomes complex. Yet the system stays essential for stable voltage control. In fact, no other method offers the same level of reliability across long transmission lines.

For deeper clarity, you can watch the linked video. It helps you see the parts and their movement in real time.

- Posted In:

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi