Switchgear Interlocks Explained for Beginners

Switchgear Interlocks Explained for Beginners https://www.theelectricalguy.in/wp-content/uploads/2025/09/maxresdefault-2-1024x576.jpg 1024 576 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gImagine removing a withdrawable type circuit breaker from a medium voltage switchgear panel while it is closed. As a result, current keeps flowing and causes severe arcing. This action can quickly start a fire or even create a worst-case scenario.

Such situations are unacceptable. Switchgear interlocks prevent these risks. In this article, we will explain switchgear interlocks for beginners. We will cover their purpose, types, and examples based on IEC standards.

Table of Contents

- What Are Switchgear Interlocks

- Purpose of Switchgear Interlocks

- Types of Switchgear Interlocks

- Examples of Switchgear Interlocks

- IEC Standard for Switchgear Interlocks

- Summary of Switchgear Interlocks

What Are Switchgear Interlocks?

The simplest definition is that interlocks in switchgear are safety systems. They prevent the switchgear from being operated incorrectly.

For example, removing a breaker while it is closed is incorrect operation. Without interlocks, dangerous conditions can occur. Interlocks prevent removing the breaker in the wrong condition. This proves the importance of using interlocks in switchgear.

All systems require mandatory interlocks. Designers can add optional interlocks based on application or customer requirements.

Purpose of Switchgear Interlocks

Switchgear interlocks serve three main purposes: safety, efficiency, and maintenance.

Safety

The primary purpose of interlocks is safety. Interlocks prevent incorrect operations of switchgear. This protects people working near the equipment.

Efficiency

Interlocks also improve efficiency. They ensure that operations are always correct. Incorrect operations can cause system failures. Proper interlocks help the switchgear work at its best.

Maintenance

Interlocks make maintenance safer. They ensure that maintenance is done only when the system is completely safe. If the system is unsafe, interlocks prevent access. This protects maintenance personnel from electric shocks or arc incidents.

Types of Switchgear Interlocks

There are two main types of interlocks: mechanical and electrical.

Mechanical Interlocks

Mechanical interlocks are common. They use physical parts to limit movement.

A simple example is a refrigerator door. The door cannot rotate fully; it stops at a certain limit. Mechanical interlocks in switchgear work the same way. They prevent wrong movements of parts.

Electrical Interlocks

Electrical interlocks work with logic and wiring. They ensure one operation happens only after a certain condition is met.

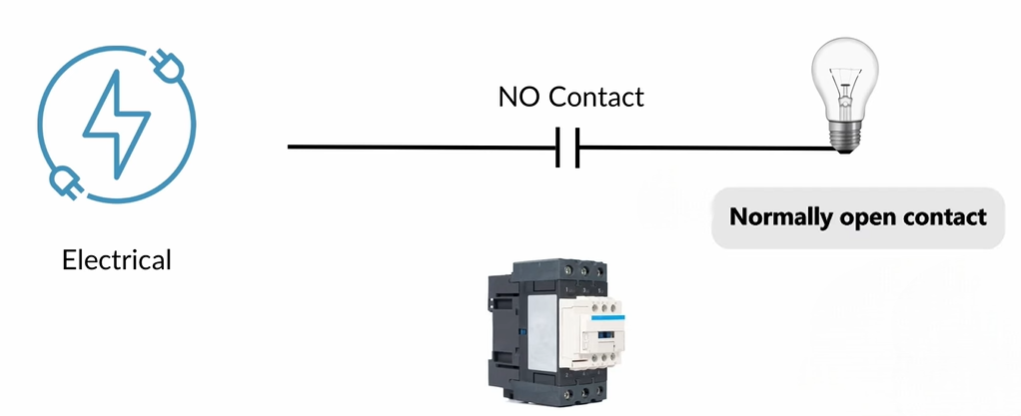

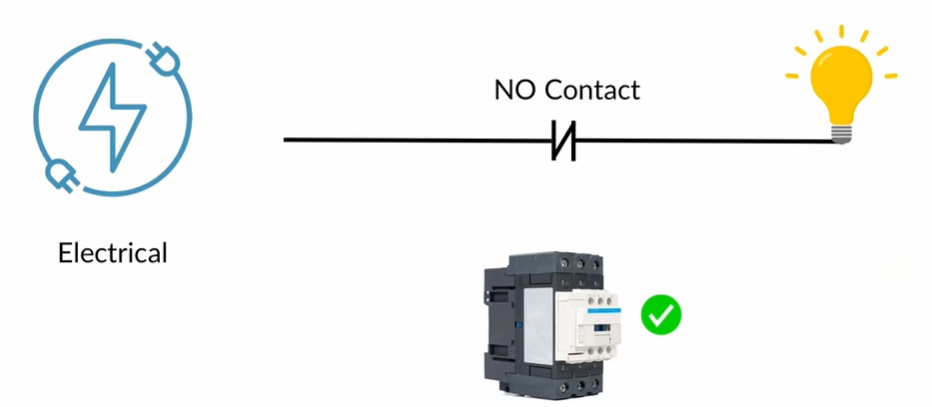

For example, imagine a light bulb connected to a DC supply through a normally open contact of a contactor.

The bulb will not turn on unless the contactor gets supply first. The contactor closes its contact and allows current to reach the bulb. This is an electrical interlock. The system enforces the correct sequence of operations.

Examples of Switchgear Interlocks

Circuit Breaker and Disconnector Interlock

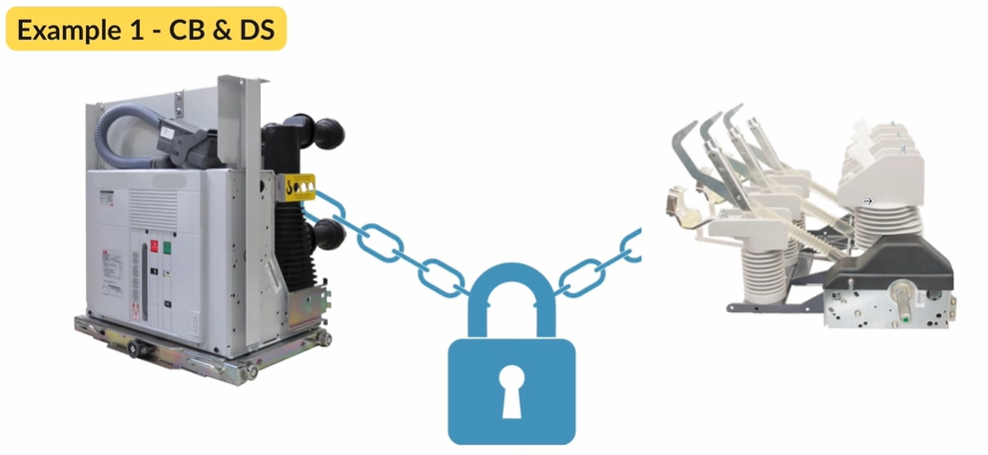

One of the most important interlocks is between a circuit breaker and a disconnector.

A disconnector is an off-load device. Therefore, it can only operate when no current is flowing. Moreover, disconnectors cannot interrupt normal or fault currents. Consequently, attempting to operate a disconnector under load causes arcing. This can be extremely dangerous and may cause fire or damage.

To prevent this, interlocks ensure the circuit breaker opens first. As a result, the breaker interrupts the current and safely handles the arc. Only then can the disconnector operate without risk.

While closing, the sequence reverses. First, the disconnector closes, and then the circuit breaker follows. In this way, the system prevents arcing and ensures safe operation.

This interlock can be mechanical, using keys and locks, or electrical, using wiring logic. IEC standards also recommend this interlock for medium voltage switchgear.

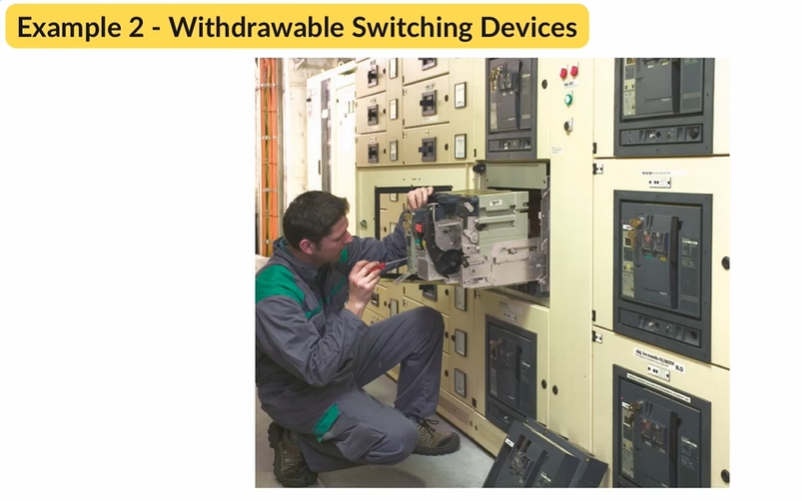

Withdrawable Type Switching Device Interlock

Another common example is the interlock for withdrawable type devices, such as withdrawable circuit breakers.

These devices can only be removed when in the open condition. Removing them while closed is unsafe. The breaker must be open to prevent current flow and arcing. This interlock is mandatory in standards and ensures safe handling of withdrawable devices.

This type of interlock applies to low voltage MCCBs and medium voltage switchgear alike.

IEC Standards for Switchgear Interlocks

The IEC standard IEC 6271-200 defines interlocks for AC metal-enclosed switchgear. It applies to voltages above 1 kV and up to 52 kV.

This standard specifies which interlocks are mandatory. Furthermore, it allows optional interlocks based on customer needs. The examples discussed above are covered under these guidelines. Additionally, engineers can add more interlocks depending on operational requirements.

Summary

We have explained switchgear interlocks for beginners in simple terms.

- Interlocks are safety systems. They prevent incorrect operations.

- The main purposes of interlocks are safety, efficiency, and safe maintenance.

- Interlocks can be mechanical or electrical.

- Key examples include interlocks between circuit breakers and disconnectors and interlocks for withdrawable devices.

- IEC standards guide the design and implementation of these interlocks.

Proper interlocks prevent accidents, ensure efficiency, and protect maintenance personnel. They are an essential part of any medium voltage switchgear.

For a better understanding, watching the video “Switchgear Interlocks Explained for Beginners | TheElectricalGuy” is highly recommended. The video visually demonstrates these concepts and examples.

- Posted In:

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi