What is Switchgear Monitoring

What is Switchgear Monitoring https://www.theelectricalguy.in/wp-content/uploads/2025/09/maxresdefault-1-1024x576.jpg 1024 576 Gaurav Joshi Gaurav Joshi https://secure.gravatar.com/avatar/f6a3006f3f7233a71d79d0e705c167ae12516870e5239627478665ae377435b3?s=96&d=mm&r=gSwitchgear is an essential part of any power system, and therefore, it plays a key role in safety. It ensures electricity flows safely and reliably. However, switchgear can develop faults over time. Even so, small issues like loose connections can eventually lead to severe accidents. This is why switchgear monitoring becomes critical, because it helps detect problems before they escalate. In addition, it provides early warnings that prevent costly failures. In this article, we will explain what switchgear monitoring is, why it is important, and how it works.

Table of Contents

- Understanding the Need for Switchgear Monitoring

- Common Hotspot Locations in Switchgear

- How Switchgear Monitoring Works

- Why Switchgear Monitoring is Important

- Parameters to Monitor in Switchgear

- Modern Methods of Switchgear Monitoring

- Advantages of Switchgear Monitoring

- Conclusion

Understanding the Need for Switchgear Monitoring

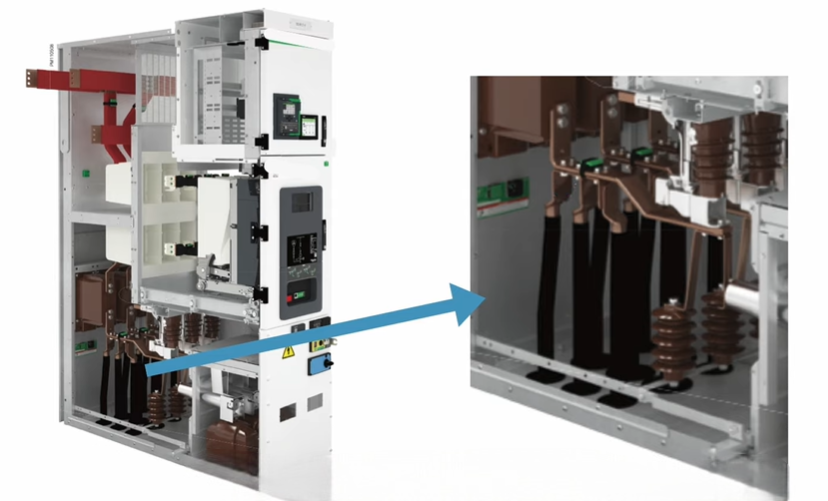

Imagine a medium voltage switchgear. The incoming cables are connected to a bus bar. While tightening the cables, a joint may not be properly tightened. This may cause tiny sparks. These sparks are often invisible to the human eye.

Over time, these sparks generate a hot spot. Initially, it is minor and hard to detect. But years later, this hot spot can cause a severe internal arc. The result can be a fire or explosion. Such incidents can harm workers nearby and damage surrounding switchgear.

A small mistake in cable connection can lead to major damage. Switchgear monitoring helps prevent such situations. It continuously tracks the condition of the switchgear. This reduces the risk of accidents and improves safety.

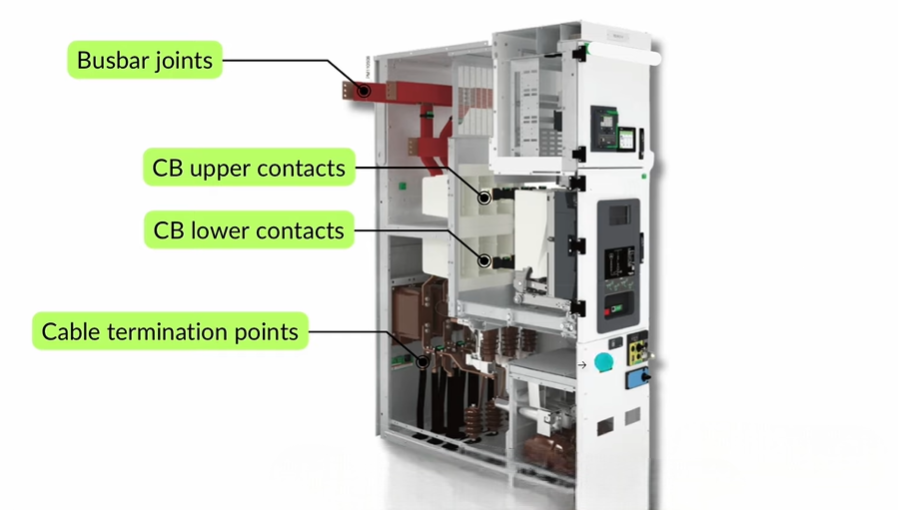

Common Hotspot Locations in Switchgear

Hotspots are common at several points in a switchgear panel. Some critical points include:

- Cable termination points

- Bus bar joints

- Circuit breaker connections

A removable or withdrawable circuit breaker used in medium or low voltage switchgear has contacts that loosen over time. Loose contacts generate sparks and heat, which happens when connecting two different panels.

For outdoor switchgear, additional risks exist. SF6 gas-filled circuit breakers are sensitive to gas leaks. If the gas leaks and the pressure drops, the breaker may lock out. In this state, it will not operate. To restore it, gas must be refilled to the required pressure.

Such problems are dangerous and can disrupt operations. Switchgear monitoring can detect these issues early and prevent failures.

How Switchgear Monitoring Works

One way to check for hotspots is using an infrared (IR) gun. This device measures temperature at specific points. If the temperature is normal, everything seems fine.

This method is not fully effective. It only gives readings at specific intervals. A fault can occur between inspections. Monitoring should be continuous.

Switchgear monitoring means continuously tracking the switchgear’s condition. It ensures safe operation and reliable power supply.

SF6 gas-filled circuit breakers often have a gas density monitor. This device measures gas density 24/7. This is real monitoring. Taking readings one time in a while is not monitoring. It is a periodic inspection.

Why Switchgear Monitoring is Important

Monitoring switchgear offers several benefits. First and foremost, the most important reason is safety. Hotspots and loose connections can lead to explosions. Therefore, switchgear monitoring helps prevent accidents and protects human life.

Another key reason is reliability. Continuous monitoring ensures that switchgear operates efficiently. When a problem occurs, it can be addressed immediately. As a result, this prevents unplanned downtime.

In addition, monitoring can predict mechanical life cycles. Advanced systems analyze trends and warn about potential failures. This way, timely maintenance can be scheduled, reducing unexpected breakdowns.

Monitoring reduces labor and cost. Personnel had to inspect switchgear, outdoor AIS substations physically. They measured temperatures, checked gas levels, and reported readings. This process was time-consuming and expensive. Modern monitoring systems automate this task. Data is collected automatically, saving labor and money.

Parameters to Monitor in Switchgear

Several parameters need monitoring to ensure safe and efficient operation. Key parameters include:

- Temperature at cable terminations and bus bar joints

- Circuit breaker performance

- Partial discharges

- Gas density in SF6 breakers

- Humidity inside the panel

High humidity inside a panel can cause electrical faults. Each parameter must be continuously monitored to detect any deviation from normal conditions.

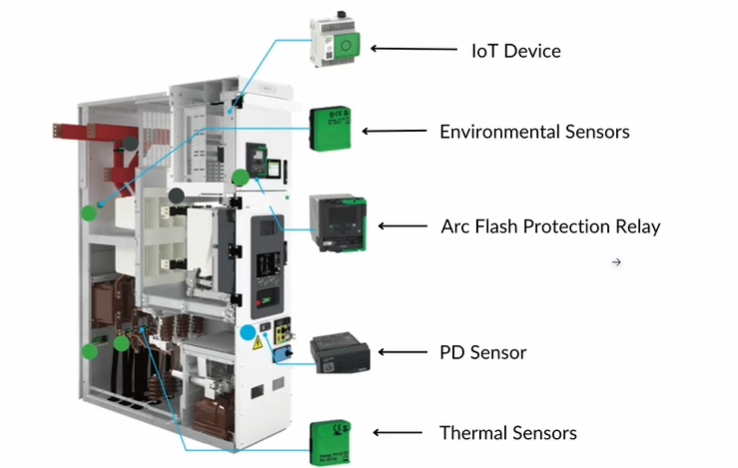

Modern Methods of Switchgear Monitoring

Old methods relied on manual inspection and temperature readings with IR guns. This was periodic and not continuous. Modern methods use advanced sensors.

Thermal sensors monitor temperature at multiple points. They provide real-time data 24/7. Partial discharge sensors detect sparks and faults in real-time. Arc flash protection relays alert in case of dangerous arcs. Environmental sensors measure humidity and other atmospheric conditions inside the panel.

All these sensors are connected to IoT devices. Data is sent to the cloud. Engineers can access this data from mobile devices anytime. This makes monitoring easier, faster, and more accurate.

Advantages of Switchgear Monitoring

Switchgear monitoring provides multiple benefits:

- Safety: Detects hazards before accidents occur. Protects workers and equipment.

- Reliability: Ensures consistent performance of switchgear. Reduces unplanned downtime.

- Predictive Maintenance: Analyzes trends to predict mechanical life cycles. Helps plan maintenance in advance.

- Cost Savings: Reduces labor and inspection costs. Data is collected automatically.

By implementing monitoring systems, industries can operate switchgear efficiently and safely.

Conclusion

Switchgear monitoring is essential for modern electrical systems. It detects hotspots, loose connections, gas leaks, and environmental changes. Continuous monitoring ensures safety, reliability, and cost savings. Modern sensors and IoT systems make it easier to monitor switchgear in real-time.

For a better understanding of switchgear monitoring, its importance, and how it works, you can watch the full video on TheElectricalGuy YouTube channel. The video explains the topic visually and gives a complete overview.

- Posted In:

- Switchgear

Gaurav Joshi

Gaurav, also known as TheElectricalGuy, is an accomplished electrical engineer with over 8 years of experience in the high and medium voltage switchgear industry. In addition to his professional endeavors, Gaurav has made significant contributions to the global electrical engineering community through his highly successful YouTube Channel. With over 240K subscribers and a prestigious silver play button from YouTube, he has become a trusted resource for electrical engineers worldwide. Gaurav's dedication to sharing knowledge extends to the creation of comprehensive courses, which have already attracted over 5000 students eager to enhance their skills in the field.

All stories by: Gaurav Joshi